By Pallet wrapper | 22 June 2022 | 0 Comments

How to choose a high quality stretch wrapping machine?

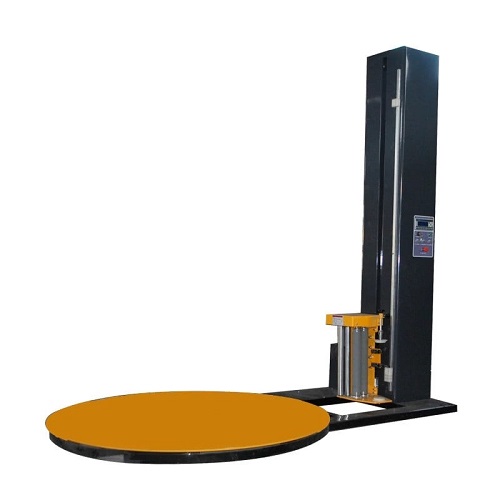

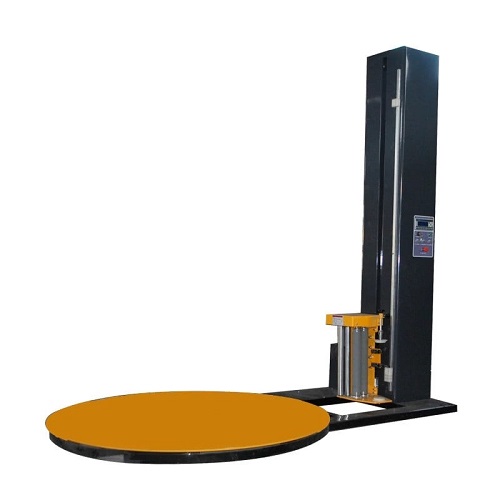

Regardless of whether it is a stretch wrapping machine, a film wrapping machine, or a stretch wrap machine, the stretch film is always used for packaging by wrapping the article, the stretch wrapped package gives protection for the articles. Especially in the logistics, chemical, and food industries, it is more used because it has a good protective layer and can effectively prevent moisture, dust and abrasion.

After understanding the functions and advantages of stretch film wrapping machines, the majority of friends in need may ask, how to choose a qualified stretch wrapping machine? Here we will briefly introduces the key components that affect the performance of the stretch wrapping machine mainly include the film carriage motor, transmission chain, turntable and other parts.

There are two types of film carriage motors on the market: DC motors and AC motors. Among them, DC motors have the advantages of fast response, soft strength not easy to break the film, no heat, stability, and power saving. However, due to the high cost and the great difficulty of controlling DC motors, so only big companies with greater strength will choose DC motors.

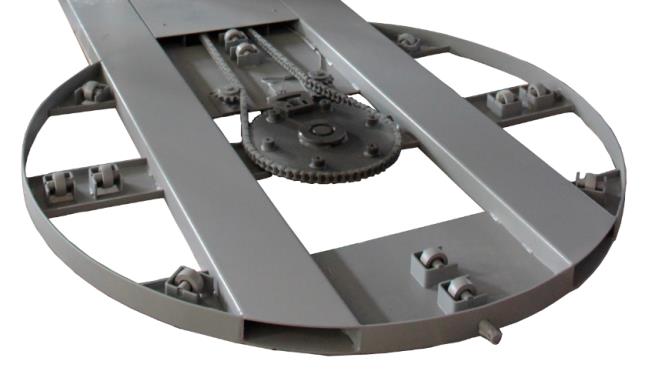

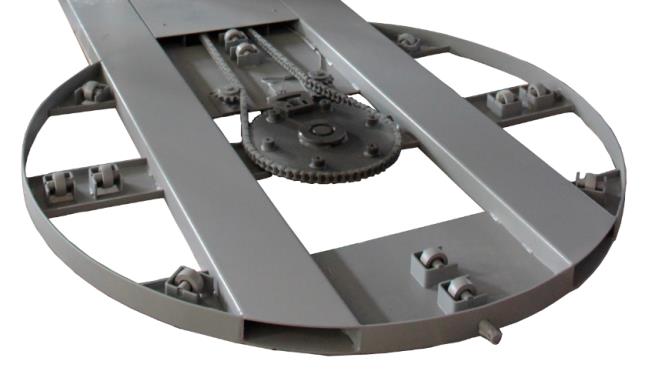

Transmission chain equipment is generally divided into two types, single chain and double chain. Double chain transmission is much better than single chain in equipment operation stability and balance.

The main attention of the turntable part is the thickness of the turntable, the diameter of the sprocket, the material of the supporting roller, etc. According to our investigation, large manufacturers generally adopt the configuration of the thickness of the turntable 10CM, the diameter of the sprocket 80 teeth, and the high-quality nylon material of the supporting roller, and the quality is guaranteed.

In order to reduce costs, some manufacturers will choose to replace the supporting wheels with a turntable thickness of 8CM, a sprocket diameter of 50 teeth, 60 teeth, plastic or inferior nylon materials. The product quality is not guaranteed, and subsequent maintenance costs will be greatly increased in the future.

After understanding the functions and advantages of stretch film wrapping machines, the majority of friends in need may ask, how to choose a qualified stretch wrapping machine? Here we will briefly introduces the key components that affect the performance of the stretch wrapping machine mainly include the film carriage motor, transmission chain, turntable and other parts.

There are two types of film carriage motors on the market: DC motors and AC motors. Among them, DC motors have the advantages of fast response, soft strength not easy to break the film, no heat, stability, and power saving. However, due to the high cost and the great difficulty of controlling DC motors, so only big companies with greater strength will choose DC motors.

Transmission chain equipment is generally divided into two types, single chain and double chain. Double chain transmission is much better than single chain in equipment operation stability and balance.

The main attention of the turntable part is the thickness of the turntable, the diameter of the sprocket, the material of the supporting roller, etc. According to our investigation, large manufacturers generally adopt the configuration of the thickness of the turntable 10CM, the diameter of the sprocket 80 teeth, and the high-quality nylon material of the supporting roller, and the quality is guaranteed.

In order to reduce costs, some manufacturers will choose to replace the supporting wheels with a turntable thickness of 8CM, a sprocket diameter of 50 teeth, 60 teeth, plastic or inferior nylon materials. The product quality is not guaranteed, and subsequent maintenance costs will be greatly increased in the future.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES