By Stretch wrapper | 12 September 2022 | 0 Comments

How to make a nice ending for the horizontal orbital wrapping?

The orbital wrapping is the most common structure for the stretch wrapping and packaging machines. Normally there is the rotating ring installed on the wrapping station and film spool is located on the rotating ring for the packaging material which includes the LLDPE stretch film and composite paper and other possible materials. The machine is rotating around the packaging objects with the spiral wrapping and wrap the products with the chosen material layer by layers controlled by the automatic PLC programme.

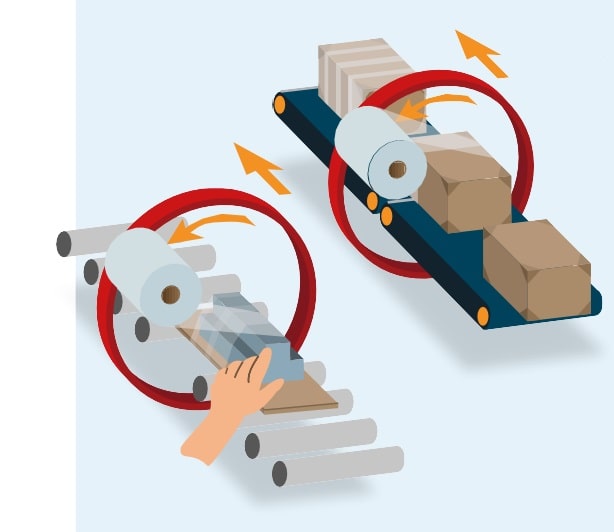

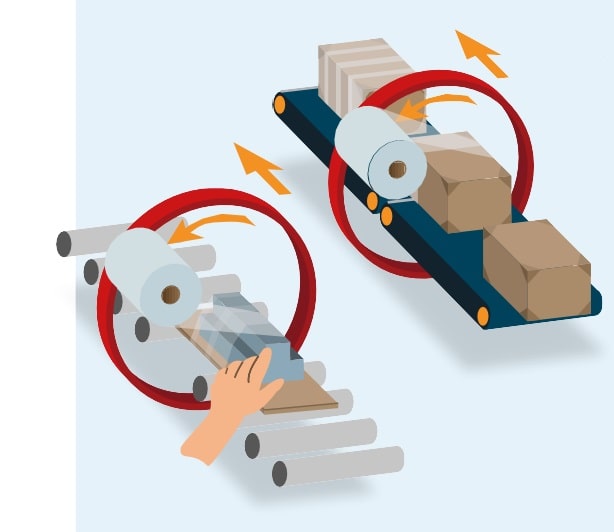

The LLDPE stretch film has the self stickness which will make the wrapped package sealed with it's self stickness. But for other materials such as the HDPE film and composite paper...... It might need to have the special tapping and labeling down by workers at the end of the wrapping. Because the machine has no such ability to have the tail of the packing material tied and the loose tail of the wrapping material will eventually make the whole package loose. So for most users like the aluminum profile manufacturers, they would prefer having their members working at each section of the whole packaging system to provide the manual assistance to the machinery. This manual assistance will bring several advantages to the investment compare to non manual assistance:

1. Nicer package. Make the package sticked and labeled will make a good exterior for selling on the market;

2. More reliable protection of the package. If the package is sticked and firmly wrapped, it's not easy to re-open during the transportation and storage. Which will keep the packaged products in a more reliable station and keep their good function;

3. Higher packaging efficiency. The manual assistance actually make the whole packaging process running smoothly and this will greatly increase the efficiency and packaging capacity.

But what about the LLDPE stretch film? It's the material which has the self stickness and will not need the extra tapping or labelling at the end of wrapping. What comes to be for the ending of LLDPE stretch film wrapping?

Actually, the ending for stretch film wrapping doesn't look good as well. Because the machine will always to a tail when the film is cut as the cutter is inevitable to have a distance from the wrapping objects. So, how can this problem to be solved? Is the manual assistance needed again for this case?

Under this circumstance, the broom design is good to choose for the solution. Install the broom mechanism under the wrapping station and sweep the LLDPE stretch film after the material is cut everytime. This sweeping will make the LLDPE stretch film stick to the package nicely just like the manual wrapping. Due to it's mechanical design, the broom sweeping is more effective and reliable than the air blowing solution, the sweeped package is always nice stack and not easy to fall again.

The LLDPE stretch film has the self stickness which will make the wrapped package sealed with it's self stickness. But for other materials such as the HDPE film and composite paper...... It might need to have the special tapping and labeling down by workers at the end of the wrapping. Because the machine has no such ability to have the tail of the packing material tied and the loose tail of the wrapping material will eventually make the whole package loose. So for most users like the aluminum profile manufacturers, they would prefer having their members working at each section of the whole packaging system to provide the manual assistance to the machinery. This manual assistance will bring several advantages to the investment compare to non manual assistance:

1. Nicer package. Make the package sticked and labeled will make a good exterior for selling on the market;

2. More reliable protection of the package. If the package is sticked and firmly wrapped, it's not easy to re-open during the transportation and storage. Which will keep the packaged products in a more reliable station and keep their good function;

3. Higher packaging efficiency. The manual assistance actually make the whole packaging process running smoothly and this will greatly increase the efficiency and packaging capacity.

But what about the LLDPE stretch film? It's the material which has the self stickness and will not need the extra tapping or labelling at the end of wrapping. What comes to be for the ending of LLDPE stretch film wrapping?

Actually, the ending for stretch film wrapping doesn't look good as well. Because the machine will always to a tail when the film is cut as the cutter is inevitable to have a distance from the wrapping objects. So, how can this problem to be solved? Is the manual assistance needed again for this case?

Under this circumstance, the broom design is good to choose for the solution. Install the broom mechanism under the wrapping station and sweep the LLDPE stretch film after the material is cut everytime. This sweeping will make the LLDPE stretch film stick to the package nicely just like the manual wrapping. Due to it's mechanical design, the broom sweeping is more effective and reliable than the air blowing solution, the sweeped package is always nice stack and not easy to fall again.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES