By Stretch wrapper | 12 September 2022 | 0 Comments

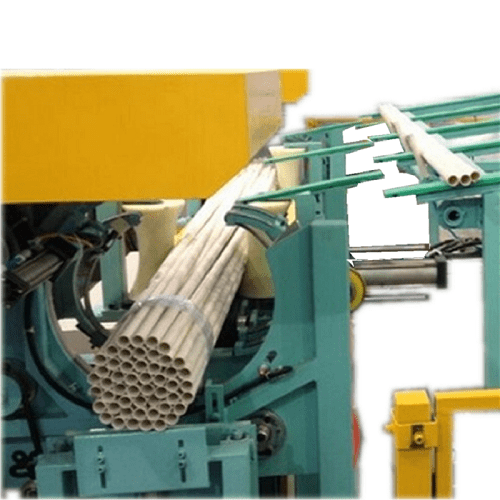

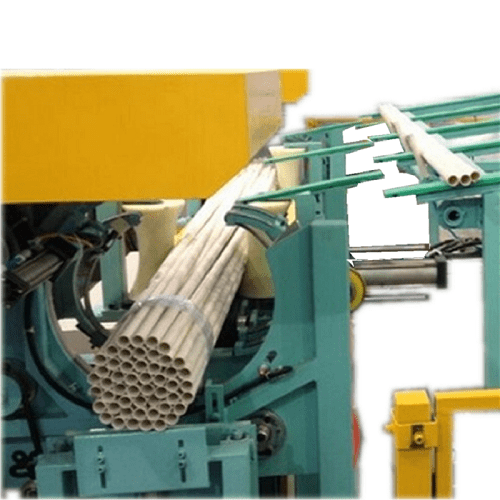

New generation of the automatic PVC pipe and tube bundling and packing line

Under the continuous improvement of the upstream automation of the plastic pipe extrusion production line (automatic conveying and batching of raw materials), also with the continuous improvement of the speed and efficiency of the extrusion production line, the packaging operation intensity of the downstream of the extrusion production line is also increasing. Based on this, we have been doing continuous exploration and innovation and a series of automatic pipe bundling and packaging machine have been launched to meet the different needs of our customers.

1. The small plastic pipe (with small diameters) packaging method:

For plastic pipes with small diameters (Φ16~32mm), according to the type of pipes produced and the quality of the pipes to be packaged, the new generation of plastic pipe bundling and bagging packaging machines generally have the following different packaging methods: For plastic PE film bag packaging, the sealing method at both ends of the bag is thermal sealed or tape wrapped; for plastic woven bag packaging, the sealing method for both ends of the bag is tape wrapping or two-fold sewing, etc.

This kind of small-diameter plastic pipe bundling and bagging packaging machine can automatically complete the process of "counting-bundling-bag-packing" for all kinds of small-diameter plastic pipes produced online. The specific automatic operation steps are as follows:

1), quality inspection sorting and storage machine

● Guide the pipes coming out of the cutting machine into the quality inspection sorting and storage machine;

● Automatically sort out the quantity and guide them into the packaging slot;

● If there are waste pipes, the pipes can be prevented from entering the packaging tank, and the pipes can be taken out manually for further processing;

● With independent measuring length for manual operation;

● The packing tank has a weighing function, if there is a weight error, it will automatically alarm and prompt manual operation.

2), Strapping by stretch film wrapping

● The strapping machine adopts the wrapping method of stretch film, and the number of wrapping layers can be freely set, and theoretically not limited by the number of times (customers can freely set within a certain reasonable range, generally less than 10 times);

● Consumables such as wrapping films and bags are equipped with automatic detection devices, which can automatically alarm and prompt manual replacement.

3), Automatic bagging section

● Bagging the bundled pipes;

● After wrapping the bag, the excess bags at both ends are folded and wrapped by adhesive tape;

● Use elevator to lift to the shelf or push the trolley, the lifting height is 1.3 meters.

4) Programmable control management system

● Adopt imported PLC system to realize signal acquisition and automatic control;

● Display production status and record production results;

● Record fault alarms and display fault points for maintenance personnel to handle and eliminate.

Such small-diameter pipe packaging has the following outstanding advantages: it can meet the above four different packaging requirements, and only need to use different packaging heads for installation under the condition that the main structure remains unchanged; Set up photoelectric counting and weighing double-layer insurance, Ensure accurate packaging quantity; The installation requires less place, saves space.

2. Packaging method of large diameter plastic pipe and tubes

For plastic pipes with larger diameters (Φ63 and above), the plastic pipe bagging packaging machine occupies a very small area, which can be adapted to the original production sites of almost all pipe manufacturers, and requires less compressed air source. , it can work normally even under the air pressure below 0.04-0.05MPA.

Aiming at the current situation of PVC pipe production technology, the automatic pipe bundling and bagging machine is adopted to make the PVC pipe directly bagged before leaving the factory, realizing automatic packaging, saving the previous four manual processes (counting, bundling, bagging, sealing) , greatly improve the production efficiency, save labor costs, and effectively avoid material waste, while reducing pollution, thereby improving economic efficiency and production efficiency. One machine can replace three workers, saving at least 150,000 labor costs per year. Calculated based on 10 extrusion production lines in each factory, 30 employees can be saved. Install an automatic packaging machine can save about 1.5 million a year.

1. The small plastic pipe (with small diameters) packaging method:

For plastic pipes with small diameters (Φ16~32mm), according to the type of pipes produced and the quality of the pipes to be packaged, the new generation of plastic pipe bundling and bagging packaging machines generally have the following different packaging methods: For plastic PE film bag packaging, the sealing method at both ends of the bag is thermal sealed or tape wrapped; for plastic woven bag packaging, the sealing method for both ends of the bag is tape wrapping or two-fold sewing, etc.

This kind of small-diameter plastic pipe bundling and bagging packaging machine can automatically complete the process of "counting-bundling-bag-packing" for all kinds of small-diameter plastic pipes produced online. The specific automatic operation steps are as follows:

1), quality inspection sorting and storage machine

● Guide the pipes coming out of the cutting machine into the quality inspection sorting and storage machine;

● Automatically sort out the quantity and guide them into the packaging slot;

● If there are waste pipes, the pipes can be prevented from entering the packaging tank, and the pipes can be taken out manually for further processing;

● With independent measuring length for manual operation;

● The packing tank has a weighing function, if there is a weight error, it will automatically alarm and prompt manual operation.

2), Strapping by stretch film wrapping

● The strapping machine adopts the wrapping method of stretch film, and the number of wrapping layers can be freely set, and theoretically not limited by the number of times (customers can freely set within a certain reasonable range, generally less than 10 times);

● Consumables such as wrapping films and bags are equipped with automatic detection devices, which can automatically alarm and prompt manual replacement.

3), Automatic bagging section

● Bagging the bundled pipes;

● After wrapping the bag, the excess bags at both ends are folded and wrapped by adhesive tape;

● Use elevator to lift to the shelf or push the trolley, the lifting height is 1.3 meters.

4) Programmable control management system

● Adopt imported PLC system to realize signal acquisition and automatic control;

● Display production status and record production results;

● Record fault alarms and display fault points for maintenance personnel to handle and eliminate.

Such small-diameter pipe packaging has the following outstanding advantages: it can meet the above four different packaging requirements, and only need to use different packaging heads for installation under the condition that the main structure remains unchanged; Set up photoelectric counting and weighing double-layer insurance, Ensure accurate packaging quantity; The installation requires less place, saves space.

2. Packaging method of large diameter plastic pipe and tubes

For plastic pipes with larger diameters (Φ63 and above), the plastic pipe bagging packaging machine occupies a very small area, which can be adapted to the original production sites of almost all pipe manufacturers, and requires less compressed air source. , it can work normally even under the air pressure below 0.04-0.05MPA.

Aiming at the current situation of PVC pipe production technology, the automatic pipe bundling and bagging machine is adopted to make the PVC pipe directly bagged before leaving the factory, realizing automatic packaging, saving the previous four manual processes (counting, bundling, bagging, sealing) , greatly improve the production efficiency, save labor costs, and effectively avoid material waste, while reducing pollution, thereby improving economic efficiency and production efficiency. One machine can replace three workers, saving at least 150,000 labor costs per year. Calculated based on 10 extrusion production lines in each factory, 30 employees can be saved. Install an automatic packaging machine can save about 1.5 million a year.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES