By Pallet wrapper | 07 October 2022 | 0 Comments

Post-stretch pallet wrapper VS pre-stretch pallet wrapping machines

For the pallet stretch wrappers, there are actually two different types of film carriages in the market. One is the post-stretch film carriage and the other is the pre-stretch film carriage. The pre-stretch type film carriage has a higher cost but it's material saving and cost saving in the long term. So, as a buyer what are their features that matter to us and which type should we choose? The below explanation will tell you which type of film carriage suits you and what pallet wrapper you need.

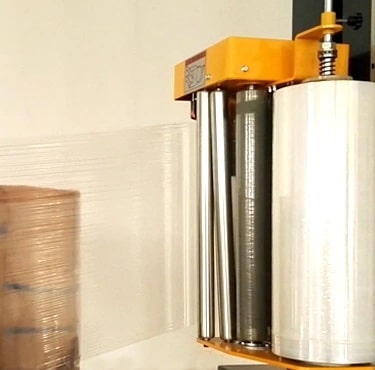

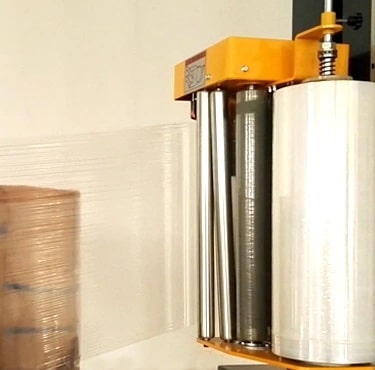

1. Post-stretch film carriage pallet wrapper:

The post stretch film carriage basically is consisted of a brake, a rubber roller and a metal roller. The adjustment of this brake will make it become difficult or easy to pull the film from the carriage. So when the wrapping starts, the film will be slightly stretched longer just like stretching by your two hands.

The post-stretch film carriage is good for wrapping heavy loads and products such as heavy cartons, barrels, buckets, cement bags or flour bags, which the film tension can be adjusted higher and won't pull off the goods and layers loaded and stacked on the pallets.

The post-stretch pallet wrapper is also a good choice for low throughput operations as it avoids the workers to walk around the pallet loads and holding the heavy rolls of stretch wrap and pulling the film difficult. The post-stretch pallet wrapper can improve the wrapping speed and make the work much easier.

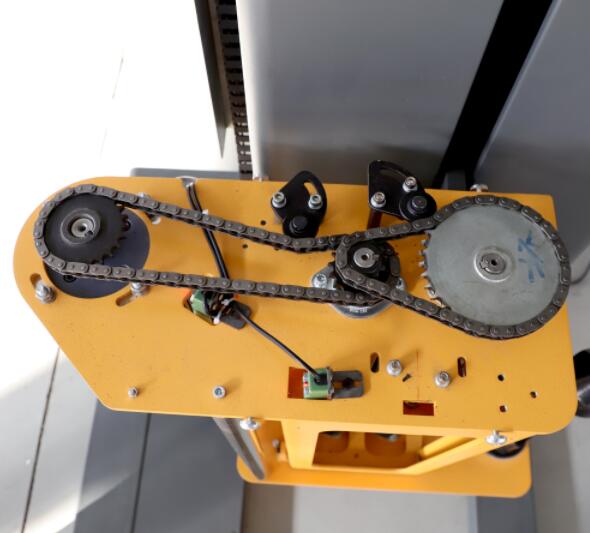

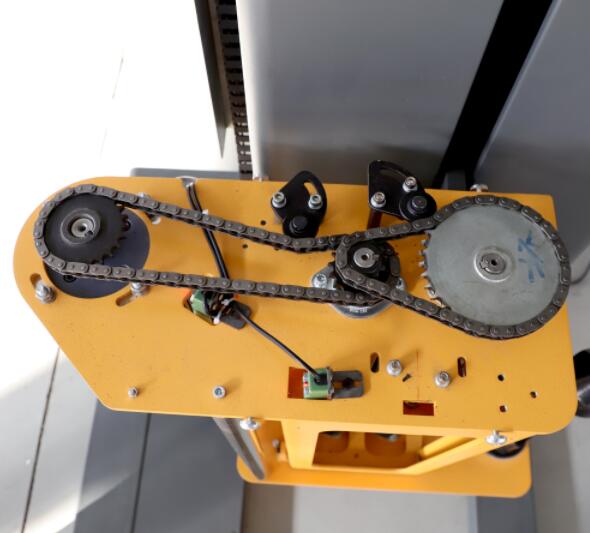

2. Pre-stretch film carriage pallet wrapper:

For high quantity of pallet loads and the very lightweight products, the pre-stretch model is a more suitable option for this kind of cases. The pre-stretch pallet wrapper can adjust the force-to-load individually which enables users either choose to set the machine to pull tightly or just wrap the pallet with very little force.

With this pre-stretch function, the stretch film will be expended to a longer length with certain ratio by electrical motor. The pre-stretched film is still keeping its memory of its original state, so it gets tighter after wrapped on the pallet loads and this will pull back the goods together and make the load secured and increase its loadability. The electrical motor connected with and controls a couple of rubber rollers, when the film comes from the film reels it will go through the geared roller system and get pre-stretched.

1. Post-stretch film carriage pallet wrapper:

The post stretch film carriage basically is consisted of a brake, a rubber roller and a metal roller. The adjustment of this brake will make it become difficult or easy to pull the film from the carriage. So when the wrapping starts, the film will be slightly stretched longer just like stretching by your two hands.

The post-stretch film carriage is good for wrapping heavy loads and products such as heavy cartons, barrels, buckets, cement bags or flour bags, which the film tension can be adjusted higher and won't pull off the goods and layers loaded and stacked on the pallets.

The post-stretch pallet wrapper is also a good choice for low throughput operations as it avoids the workers to walk around the pallet loads and holding the heavy rolls of stretch wrap and pulling the film difficult. The post-stretch pallet wrapper can improve the wrapping speed and make the work much easier.

2. Pre-stretch film carriage pallet wrapper:

For high quantity of pallet loads and the very lightweight products, the pre-stretch model is a more suitable option for this kind of cases. The pre-stretch pallet wrapper can adjust the force-to-load individually which enables users either choose to set the machine to pull tightly or just wrap the pallet with very little force.

With this pre-stretch function, the stretch film will be expended to a longer length with certain ratio by electrical motor. The pre-stretched film is still keeping its memory of its original state, so it gets tighter after wrapped on the pallet loads and this will pull back the goods together and make the load secured and increase its loadability. The electrical motor connected with and controls a couple of rubber rollers, when the film comes from the film reels it will go through the geared roller system and get pre-stretched.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES