By Pallet wrapper | 21 June 2022 | 0 Comments

Why should the goods in the warehouse be wrapped with a layer of plastic film?

1. The main function of the stretch film is about the protection of the products stacked on the pallet in order to prevent the goods from collapsing during the transfer or storage. Usually when receiving the goods, it seems that the goods are protected with stretch film, and when the goods are shipped in bulk, the stretch film is removed.

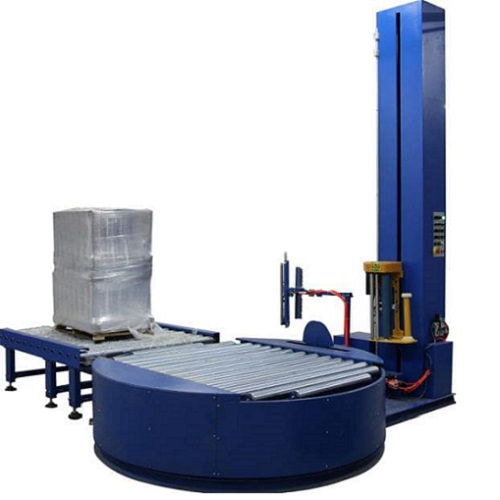

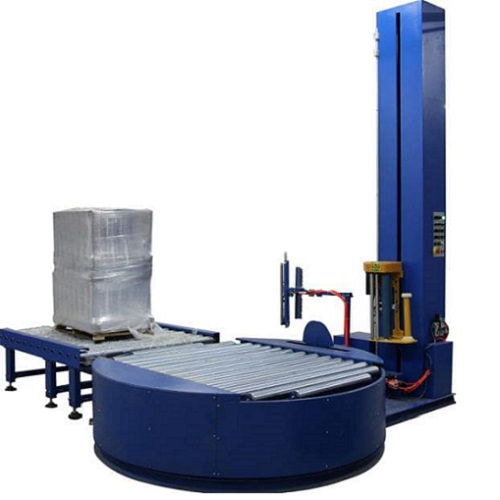

There are two main ways of winding this film to wrap pallets, one is machine wrapping and the other is hand wrapping. Both methods have their own advantages and disadvantages, and they need to be selected according to the actual situation.

If the machine wraps the film, the action is set in advance, and it is more standardized. The wrapped pallets are more tight with good tension as the pallet packers have this pre-stretch function. However, the wrapping of the offline products of the non-production factory usually requires a forklift and forklift driver to cooperate with the operation (some use pallet jack/pallet truck, and need a ramp to go Push up), mainly to put the stacked products on the film wrapping machine with a forklift. Hand wrapping is not easy to standardize because there are many operators, especially the strength of wrapping.

2. The cost of stretch film:

Stretch film is a non-reusable material for the warehouse. When receiving the goods, use stretch film for protection. When shipping in bulk, you need to remove the stretch film from the goods. In addition, if there is a situation where the reel is shipped, it also needs to be protected with stretch film. Because the stretch film cannot be reused, the cost of stretch film is not a small cost for warehouses with a relatively large amount of use.

The cost is mainly the purchase cost, and then, after subtracting the income obtained after the waste stretch film is sold as a waste product, it constitutes the actual cost of the stretch film. Some manufacturers sell by roll (each roll has specifications), and some sell by weight.

3. How to do cost control:

First of all, it is recommended to plan with the annual quantity when purchasing, to purchase the suppliers of stretch film, and reduce the price through the quantity. Or negotiate a tiered price with the supplier, that is, what is the unit price within the number of rolls, and how much is the unit price after it is exceeded.

Secondly, you can optimize the wrapping method. For example, for the extremely unstable stacking, wrap 3 layers, and the stacking is relatively stable. Only the two layers of goods on the top of the pallet are wrapped to protect, so that each pallet can be saved. Less amount of stretch film used.

Third, for some relatively stable goods, purchase some reusable "magic belts" to replace stretch film. The above three methods can reduce the cost of stretch film to a certain extent.

Summary:

A layer of plastic film wrapped around the goods in the warehouse is actually a stretch film used to prevent the goods from collapsing during parallel movement or storage;

stretch film is a one-time consumable, and it can be regarded as a large-use warehouse. A lot of expenses; you can control the expenses through the three methods described above.

There are two main ways of winding this film to wrap pallets, one is machine wrapping and the other is hand wrapping. Both methods have their own advantages and disadvantages, and they need to be selected according to the actual situation.

If the machine wraps the film, the action is set in advance, and it is more standardized. The wrapped pallets are more tight with good tension as the pallet packers have this pre-stretch function. However, the wrapping of the offline products of the non-production factory usually requires a forklift and forklift driver to cooperate with the operation (some use pallet jack/pallet truck, and need a ramp to go Push up), mainly to put the stacked products on the film wrapping machine with a forklift. Hand wrapping is not easy to standardize because there are many operators, especially the strength of wrapping.

2. The cost of stretch film:

Stretch film is a non-reusable material for the warehouse. When receiving the goods, use stretch film for protection. When shipping in bulk, you need to remove the stretch film from the goods. In addition, if there is a situation where the reel is shipped, it also needs to be protected with stretch film. Because the stretch film cannot be reused, the cost of stretch film is not a small cost for warehouses with a relatively large amount of use.

The cost is mainly the purchase cost, and then, after subtracting the income obtained after the waste stretch film is sold as a waste product, it constitutes the actual cost of the stretch film. Some manufacturers sell by roll (each roll has specifications), and some sell by weight.

3. How to do cost control:

First of all, it is recommended to plan with the annual quantity when purchasing, to purchase the suppliers of stretch film, and reduce the price through the quantity. Or negotiate a tiered price with the supplier, that is, what is the unit price within the number of rolls, and how much is the unit price after it is exceeded.

Secondly, you can optimize the wrapping method. For example, for the extremely unstable stacking, wrap 3 layers, and the stacking is relatively stable. Only the two layers of goods on the top of the pallet are wrapped to protect, so that each pallet can be saved. Less amount of stretch film used.

Third, for some relatively stable goods, purchase some reusable "magic belts" to replace stretch film. The above three methods can reduce the cost of stretch film to a certain extent.

Summary:

A layer of plastic film wrapped around the goods in the warehouse is actually a stretch film used to prevent the goods from collapsing during parallel movement or storage;

stretch film is a one-time consumable, and it can be regarded as a large-use warehouse. A lot of expenses; you can control the expenses through the three methods described above.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES