By Mold tilter and upender | 09 December 2020 | 0 Comments

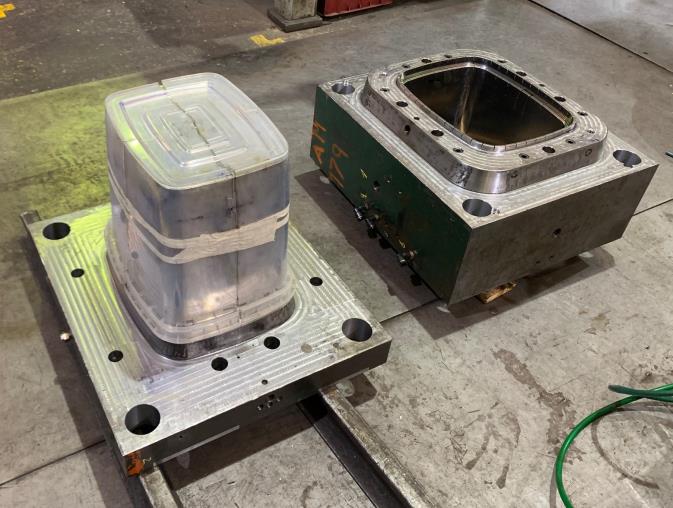

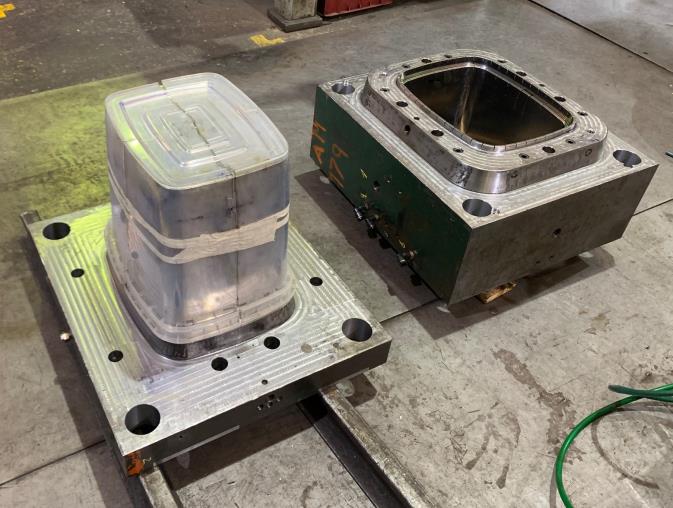

Mold flipper and die turnover machine for injection moulding

The injection moulding is one of the manufacturing process to produce different parts by injecting molten plastic or metal material to a mould or mold which is the U.S. spelling, so it's also called injection molding or die-casting. The raw material includes glass, elastomers, thermoplastic, metal.......First step is to melt the material into a heated barrel then inject to a mold cavity where it will cool down and harden to a configuration.

After the whole mold is cooled down and the figure is formed, the workers need to reverse the mold and pour the formed parts out to do the further treatment. This action of reverse maybe easy if the mold is small and lift, but for large heavy mold especially with it fulfilled with material, the whole part is very heavy to turnover. At this time, we need to use mold flipper to turnover the mold 90 degree. This machine is also known as mold tilter, it's a necessary machinery for injection molding processes.

After the whole mold is cooled down and the figure is formed, the workers need to reverse the mold and pour the formed parts out to do the further treatment. This action of reverse maybe easy if the mold is small and lift, but for large heavy mold especially with it fulfilled with material, the whole part is very heavy to turnover. At this time, we need to use mold flipper to turnover the mold 90 degree. This machine is also known as mold tilter, it's a necessary machinery for injection molding processes.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES