By shrink wrapper | 05 December 2020 | 2 Comments

The packing solution for XPS foam insulation boards

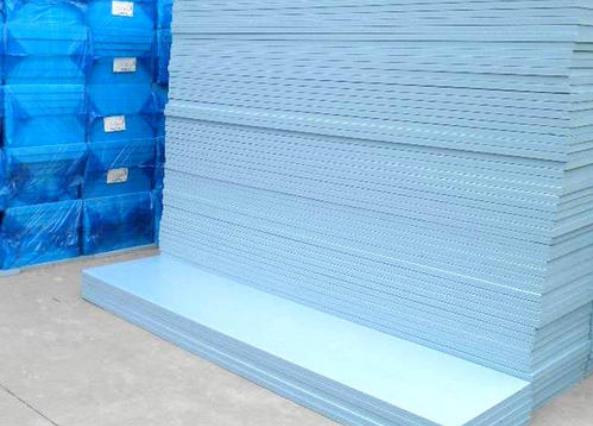

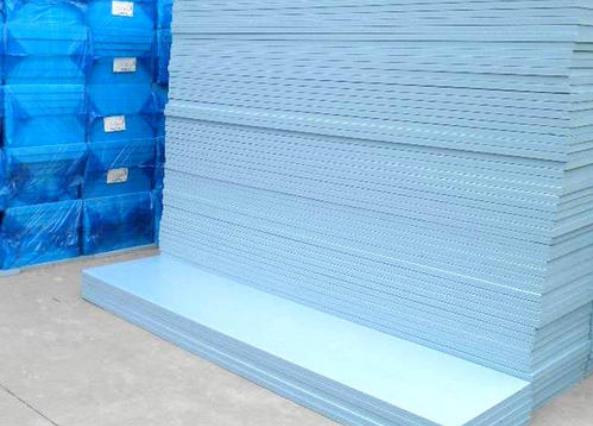

XPS boards are made by extruding polystyrene foam and also formed with polystyrene polymer. The boards are rigid insulated which manufactured by using an extrusion process often with the distinctive colors for identifying the product.

The XPS foam is very light in weight and is a very flexible insulation solution which is resistant to water absorption, these qualities make it the most ideal material for application of building construction.

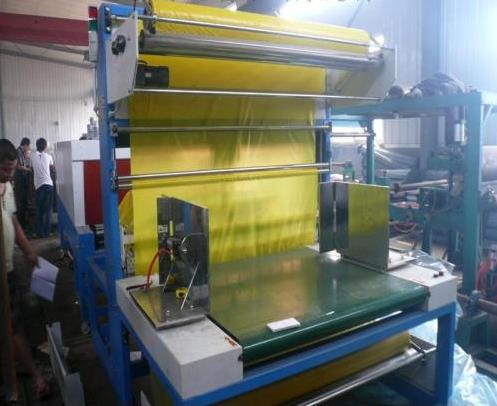

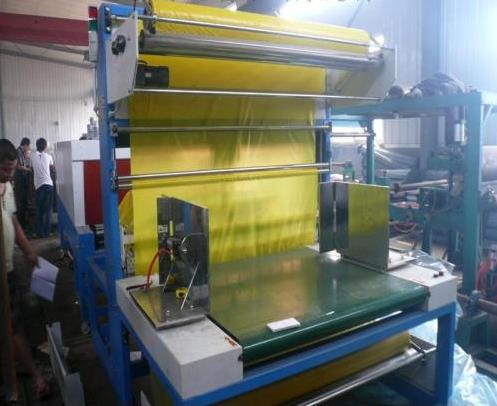

Emanpack has shrink wrap machine for XPS insulation boards protection and packaging. The machine which belongs to sleeve shrink wrapper, it covers the bundle of XPS boards with a layer of PE film. A heat sealing blade to weld the side and leaving the two ends unsealed. After shrinking through the heat shrink tunnel, the film is wrapped tight to the products and the package is very nice and beautiful.

This machine is very fast and efficient, the boards could be induced to the in-feed conveyor by connected to your production line, which is fully automatic and no need for any manual assistance. It also can have a pusher for light products to pushed to the machine for sealing. By working with you closely, we can do more improvement in order to give you the best machine you want.

The XPS foam is very light in weight and is a very flexible insulation solution which is resistant to water absorption, these qualities make it the most ideal material for application of building construction.

Emanpack has shrink wrap machine for XPS insulation boards protection and packaging. The machine which belongs to sleeve shrink wrapper, it covers the bundle of XPS boards with a layer of PE film. A heat sealing blade to weld the side and leaving the two ends unsealed. After shrinking through the heat shrink tunnel, the film is wrapped tight to the products and the package is very nice and beautiful.

This machine is very fast and efficient, the boards could be induced to the in-feed conveyor by connected to your production line, which is fully automatic and no need for any manual assistance. It also can have a pusher for light products to pushed to the machine for sealing. By working with you closely, we can do more improvement in order to give you the best machine you want.

Recently Reviews

Read MoreLeave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES