The automatic packaging machine replaces traditional manual packaging, not only can guarantee the quality of packaging, but also save labor, reduce labor intensity, and at the same time make working conditions and working environment improved. The automatic packaging machine also has the advantages of high production efficiency, simple production, high degree of automation, and less space. Therefore, automatic packaging machinery has been widely used in various fields such as food, paper, light industry, electromechanical, household appliances, and chemical industries.

At present, there are a wide variety of packaging machinery, each with its own characteristics, and is developing in the direction of improving technical parameters, serialization, and automation, and there are more and more special-purpose machines. Automatic packaging machinery has become a general-purpose machinery widely used in various sectors of the national economy.

The

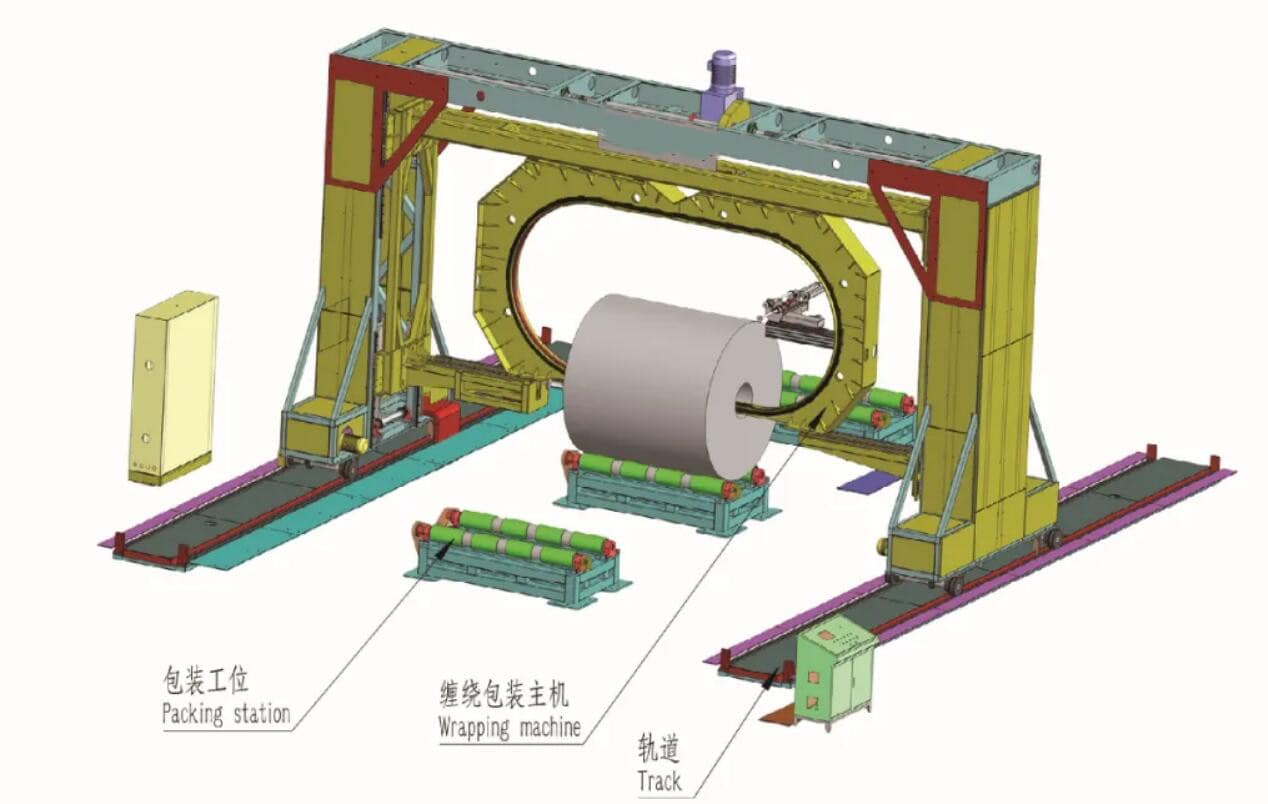

coil master wrapping machine is mainly used for winding and packaging large and long circular products, especially composite winding packaging that can simultaneously use multiple film materials to complete circular products at one time. This kind of ring-shaped products are mainly high-grade wire coils,

7 wire PC strand and steel coils, which can prevent wear, dust, moisture, and cleanliness by packaging them.

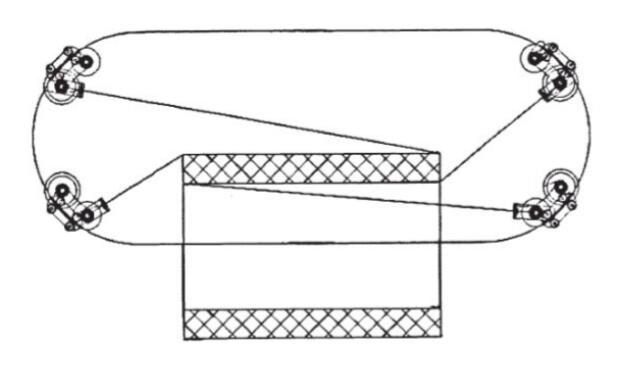

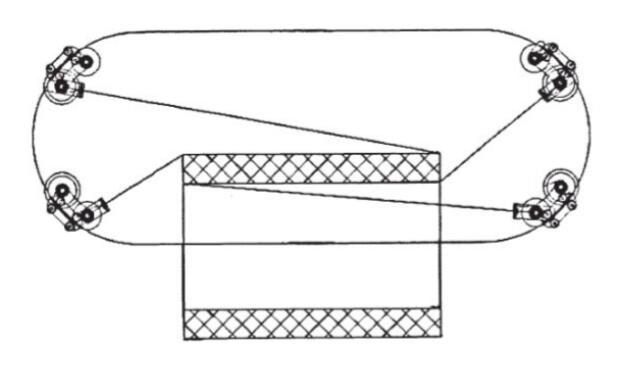

The ring in the figure is the moving guide rail carrying the chain of the packaging mechanism, and the ring guide rail is divided into two parts, left and right. When the packaging machine is working, the left and right guide rails move towards the middle to form a closed guide rail system. Four symmetrically distributed four motors respectively drive the chain carrying the packaging mechanism to move on the guide rails through the gears driven by the reducer. The workpiece is loaded by the Driven by the drive system on the trolley, the coordinated movement of the packaging mechanism and the workpiece on the loading trolley is realized through the control system, so as to realize the one-time packaging of multiple materials for the workpiece.

Basic design requirements for installation:

⑴ Outer dimensions of wire coil: Outer diameter: 1300mm: Inner diameter: 700mm; Length: 2300mm;

Weight: 2500kg;

(2) Shuttle trolley speed: 6 m/s;

(3) Each lap time of the shuttle trolley: 1.6 s;

(4) Movement speed of cylinder piston: 0.8m/s;

(5) U-shaped door opening and closing time: 2s;

(6) U-shaped door stroke: 1300mm.