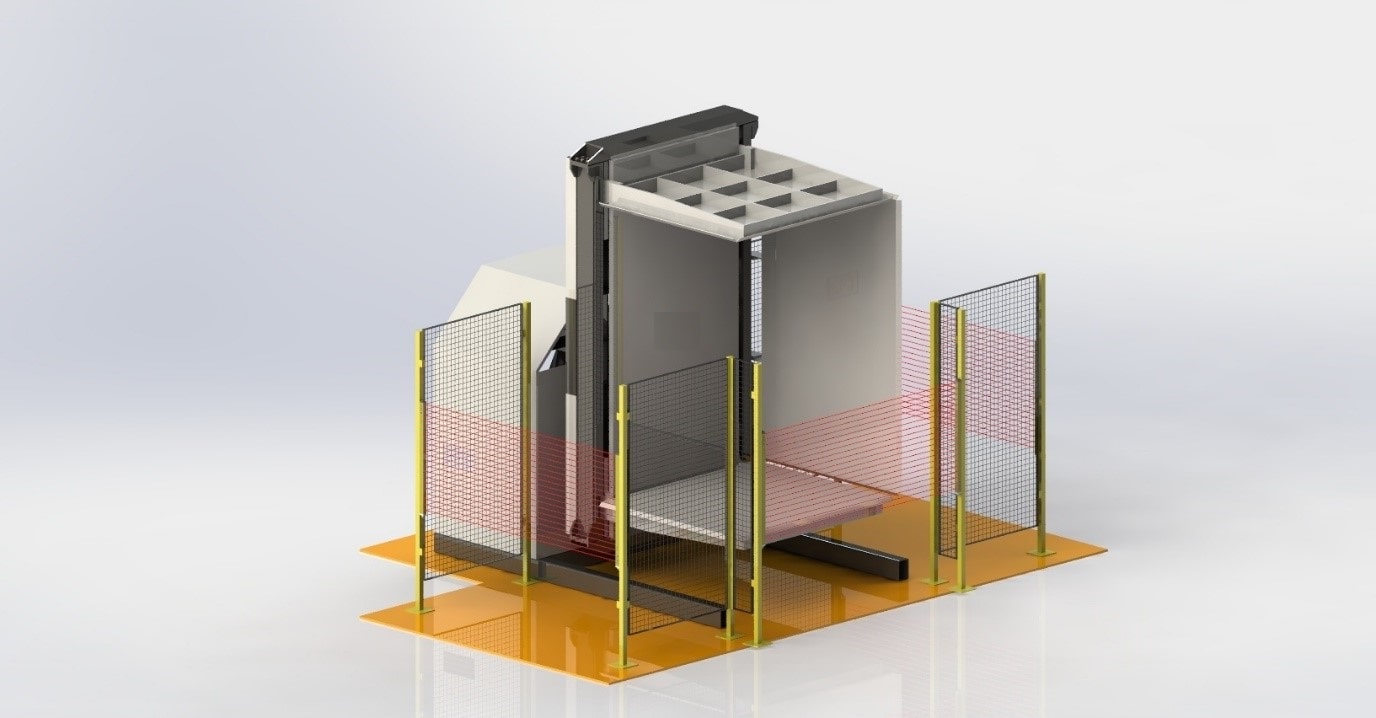

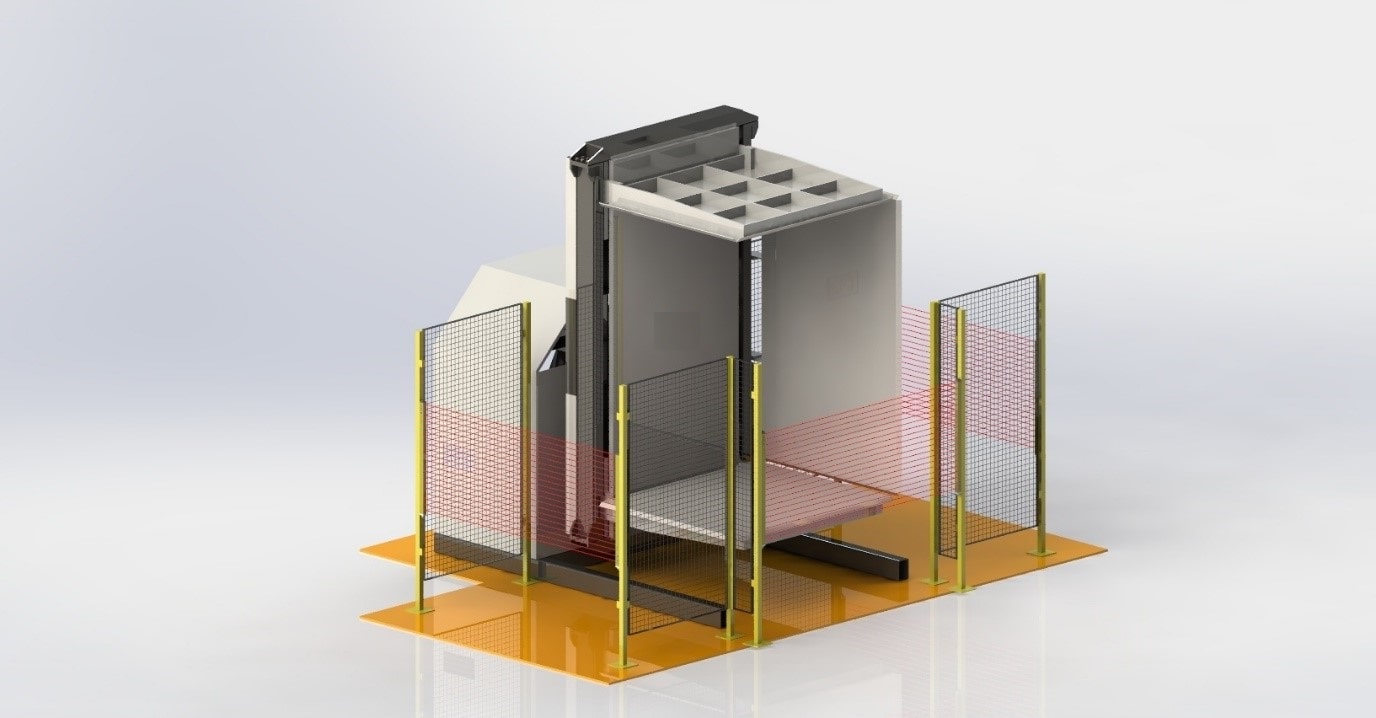

Industrial turning machine is a common machine for industrial production especially the mechanical area. It can adapt to the turning requirements of different specific goods and objects, provide the safe, stable and effective turnover process within the transportation, and realize the conversion of goods from horizontal to vertical or vertical to horizontal position which is the goal of the job.

It is widely used in metallurgy, stamping, sheet metal, mold, paper making, cold storage, steel belt, wire reel, barrel material, coil material and other industries. So what kinds of turning machines are there? Today we will share the common classifications of turning machines in the industry to you:

First, the turning machine can be divided into 90° turning machine and 180° turning machine according to the maximum turning angle.

The 90 degree turning machine has the steel coil upender, mold flipper and the 180 degree turning machine are mainly focus on the pallet loads. This includes the 180 degree

pallet inverter and pile turner. Pallet inverter desinged for easier exchange of the pallets applied to warehouse when plastic system pallets needs to be replaced by the wooden shipping pallets. The pile turner is designed mainly for aligning and preparing the paper stack and removing the impurity before printing.

Second, according to the performance, industrial turning machine can be divided into steel coil turning machine, mold turning machine and plate turning machine.

1. The steel coil turning machine realizes that the heavy steel coil can be hoisted to the V-shaped surface of the turning machine, and the steel coil can be placed flat on the pallet through 0-90° overturning. The machine is often named as steel coil upender.

2. Mold turning machine, when repairing large and medium-sized molds, it can turn the mold over 0-90°, which is convenient, labor-saving and safe to open, close and lift the mold. It is an indispensable auxiliary equipment for the stamping workshop and an ideal equipment for repairing large molds. For the people who work in this industry, it's also called

tool flipper machine.

3. The plate turning machine is a special equipment produced in the automobile industry. It is used for turning large thin plate stacks. It is a necessary auxiliary equipment for the stamping automation production line. It not only reduce the surface scratches of the plate, improve the product quality, but also reduce the operator’s Labor intensity improves production efficiency.