Highly automated orbital stretch wrapping machine, HM-A500 is a model for packing large bundles such as aluminum extrusion, PVC pipes, steel tubes, long cartons, timber posts and panels......

Our self designed PLC program helps you reduce human interference for operation and management.

Frequency inverters for regulating the speed of conveyors and wrapping ring rotation, slow start and stop avoid damages to the motors and extend the machine's worklife.

Features

Automatic system controlled by PLC and program, less manual assistance is needed.

Suitable for long shape products wrapping such as rods and profiles.

High speed rotating ring, increase the capacity and reduce wrapping time.

Photoelectricity for detecting the bundles and starts wrapping automatically.

Automatic packing material cutter and feeder, cut and clamp the packing material for the next turn.

Different packing materials are appliable, for instance stretch film, composited paper, HDPE film, woven belt.....

Conveyor speed and ring speed are adjustable through frequency converter.

Machine is available to connect with customer's production line for automatic packing process.

Top press rollers and protective side rollers to fix the product and keep it stationary.

Technical Parameter

| Packing size | |

| Length | 800mm-unlimited |

| Width | 150mm-400mm |

| Height | 150mm-300mm (available to customize) |

| Max weight | upon customer's requirement |

| Film roll dimension | |

| ID | 50mm |

| OD | max 250mm |

| Width | 100-200mm |

| Stretch film thickness | 20-35 microns |

| Speed of ring rotation | 90-100rmp |

| Overlapping rate | 15-90% |

| Wrapping speed | 5-14m/min |

| Operation mode | automatic operation |

| Power supply | 380V, 3Ph, 50/60Hz( available to customize) |

| Output | 1.5kw |

Options

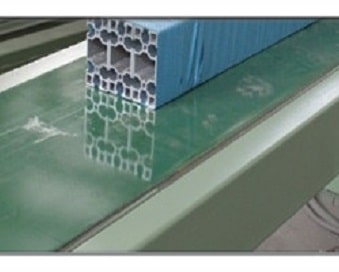

Conveyor

conveyor belt, roller table, chain conveyor and chain board conveyor are optional, size depends on customer

Material cutter

Different types of film cutter for different packing material are available to choose

Film spool

Two film spools double the speed of wrapping