By Pallet wrapper | 16 April 2022 | 0 Comments

Abnormal sound from the turntable of the pallet packer machine

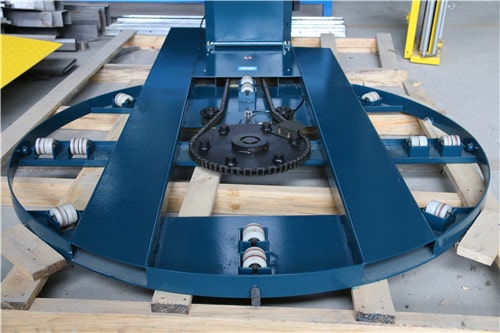

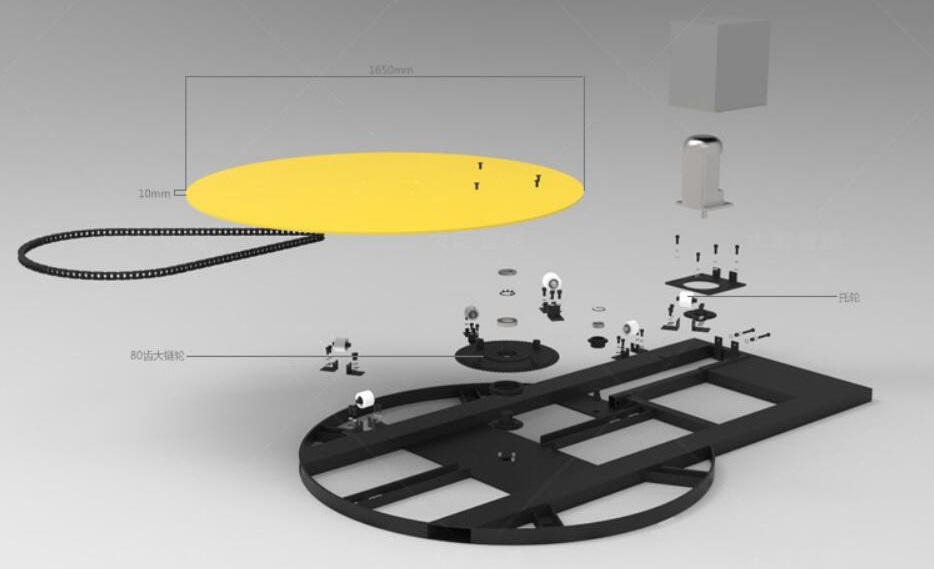

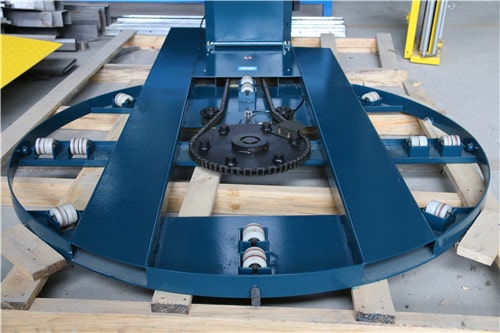

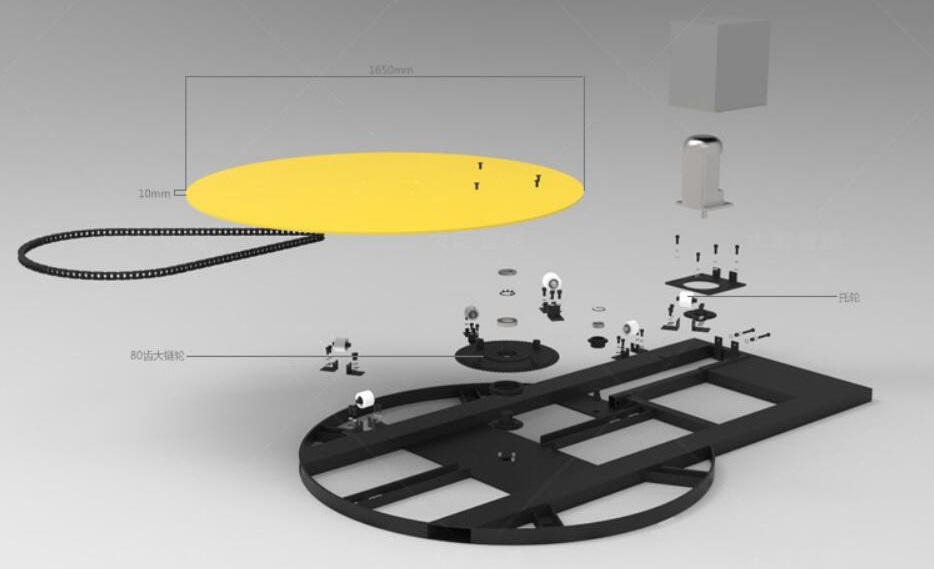

The pallet packer machine is an increasingly common equipment on the downstream packaging production line. It can significantly improve packaging efficiency, save packaging material, and reduce labor intensity. What we want to share with you today is the reason for the abnormal sound of the turntable. This actually refers to the bearing rollers under the turntable. The material of the roller is nylon, so there will be wear after a long time of use, but what conditions will aggravate the wear? Next, we will take you to find out.

1. The equipment is not placed evenly.

During installation, if the pallet packer machine is not placed on a flat ground, the chain will not be in a horizontal position when rotating, so the turntable will shake, and the rollers will be unevenly stressed. This situation will aggravate the wear of the roller. And it will also produce obvious abnormal noise.

2. The weight of the cargo is too large.

A standard pallet packer machine has its effective load, which is generally 2000kg. If the weight of the cargo often exceeds 2000kg in daily use, it will aggravate the wear of the rollers, and in severe cases, it will cause the turntable motor to be overloaded and affect its life.

3. The roller is broken.

This situation is generally caused by a sudden severe impact on the turntable. When it breaks due to the impact, if the damaged roller is not dealt with immediately, the damaged roller will be replaced, which will cause uneven force on the turntable and affect other rollers. , Causing follow-up questions.

The above are some experience summarized on the turntable wear of the pallet packer machine. Everyone must take the problem seriously when using it, and it is best to report the problem to the equipment manufacturer as soon as possible.

1. The equipment is not placed evenly.

During installation, if the pallet packer machine is not placed on a flat ground, the chain will not be in a horizontal position when rotating, so the turntable will shake, and the rollers will be unevenly stressed. This situation will aggravate the wear of the roller. And it will also produce obvious abnormal noise.

2. The weight of the cargo is too large.

A standard pallet packer machine has its effective load, which is generally 2000kg. If the weight of the cargo often exceeds 2000kg in daily use, it will aggravate the wear of the rollers, and in severe cases, it will cause the turntable motor to be overloaded and affect its life.

3. The roller is broken.

This situation is generally caused by a sudden severe impact on the turntable. When it breaks due to the impact, if the damaged roller is not dealt with immediately, the damaged roller will be replaced, which will cause uneven force on the turntable and affect other rollers. , Causing follow-up questions.

The above are some experience summarized on the turntable wear of the pallet packer machine. Everyone must take the problem seriously when using it, and it is best to report the problem to the equipment manufacturer as soon as possible.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES