By Stretch wrapper | 12 September 2022 | 0 Comments

Do you really know stretch film?

With the soaring price of raw materials for stretch film this year, the price of stretch film has continued to rise, but do you really understand the composition of stretch film? Among them, some of the key indicators of stretch film, such as stretch, transparency, and viscosity, are what really determines it. After understanding these, you will know why some stretch films are so expensive but has good quality. We must not choose the stretch film because of its low price, but to compare the unit cost. Today, we will take you to a deeper understanding of stretch film.

First, let’s look at the composition of the stretch film. Unlike food-grade cling film, the stretch film on the market is generally processed from raw materials such as LLDPE and metallocene compounds. The quality of the stretch film depends on the amount of metallocene compound added. The metal compound has good processing performance, high strength, good rigidity and transparency, and has very good performance in terms of temperature resistance and chemical resistance. The addition of metallocene compounds to a certain level can greatly improve the performance of the stretch film. But this will also increase the cost.

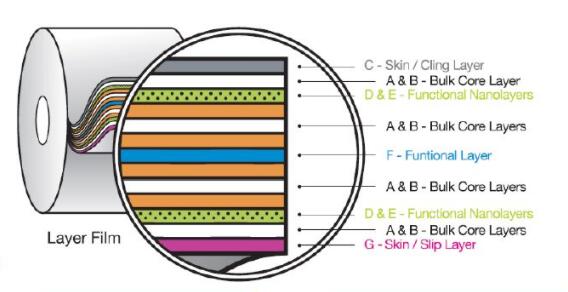

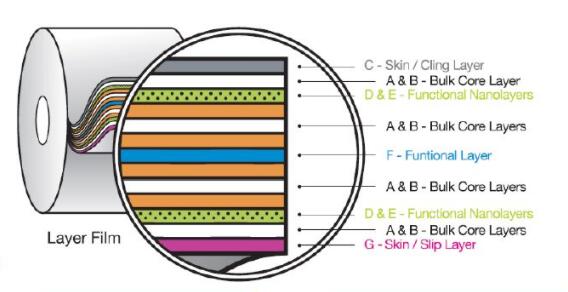

Let’s look at the production process of stretch film. The current stretch film generally adopts multi-layer co-extrusion technology. By adjusting the ratio of various compounds and adding some special substances, it can achieve single-sided or double-sided viscosity, colorless, odorless, shrinking, etc. characteristic. Another way to make the film sticky is to add glue particles uniformly on the film during the production of the stretch film. However, the disadvantage of the stretch film produced by this method is that after the film is stretched by 2 times or 3 times longer, the viscosity of the glue particles is reduced. And it will be greatly reduced. After the wrapping is completed, it is easy to cause the film ends to fall off, and the thickness of this film is generally relatively large, and it does not feel smooth to the touch and has a clear grainy feel.

Everyone must pay attention when choosing industrial stretch film. It is not that the thicker the film, the better the stretchability and penetration resistance of the film. The thicker the film, the shorter the length per kilogram. Both thin film and thick film have different applicability. For carton-packed goods, thin stretch film can play a very good wrapping, while for irregular stacking, heavier and loose goods, It is better to choose the thicker stretch film.

First, let’s look at the composition of the stretch film. Unlike food-grade cling film, the stretch film on the market is generally processed from raw materials such as LLDPE and metallocene compounds. The quality of the stretch film depends on the amount of metallocene compound added. The metal compound has good processing performance, high strength, good rigidity and transparency, and has very good performance in terms of temperature resistance and chemical resistance. The addition of metallocene compounds to a certain level can greatly improve the performance of the stretch film. But this will also increase the cost.

Let’s look at the production process of stretch film. The current stretch film generally adopts multi-layer co-extrusion technology. By adjusting the ratio of various compounds and adding some special substances, it can achieve single-sided or double-sided viscosity, colorless, odorless, shrinking, etc. characteristic. Another way to make the film sticky is to add glue particles uniformly on the film during the production of the stretch film. However, the disadvantage of the stretch film produced by this method is that after the film is stretched by 2 times or 3 times longer, the viscosity of the glue particles is reduced. And it will be greatly reduced. After the wrapping is completed, it is easy to cause the film ends to fall off, and the thickness of this film is generally relatively large, and it does not feel smooth to the touch and has a clear grainy feel.

Everyone must pay attention when choosing industrial stretch film. It is not that the thicker the film, the better the stretchability and penetration resistance of the film. The thicker the film, the shorter the length per kilogram. Both thin film and thick film have different applicability. For carton-packed goods, thin stretch film can play a very good wrapping, while for irregular stacking, heavier and loose goods, It is better to choose the thicker stretch film.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES