By Pallet wrapper | 21 June 2022 | 0 Comments

The use and maintenance of pallet stretch wrapping machine

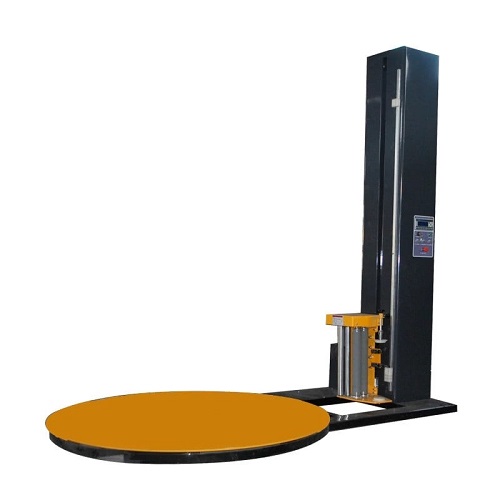

Pallet stretch wrapping machine is a large packaging equipment used by many customers now. This equipment is mainly used to wrap pallets with stretch film. It is a relatively large packaging equipment. Therefore, after purchasing the pallet stretch wrapping machine, the customer must formulate the corresponding Safety operating procedures, the following briefly introduces the safe operating procedures of the pallet stretch machine:

1. Before the operation of the pallet stretch machine:

confirm the power supply used by the stretch wrapping machine, and do not plug in the wrong power supply. The voltage of the machines produced by each equipment manufacturer is not uniform, and the grounding wire must be used for leakage protection.

Check whether the stretch film is threaded correctly.

Check whether the power wire insulation is intact.

Whether the machine operates normally during empty running.

There is also the need to formulate corresponding operators to operate and conduct special training.

2. The pallet stretch wrapping machine is in operation:

When the machine is running, it is strictly forbidden to step on the turntable of the machine.

It is not allowed to install the machine in a soft place.

It is not allowed to rinse the machine with water. If the workplace is humid, the operator should not work barefoot.

It is not allowed to place objects to be wound on the edge of the turntable.

In an emergency, you can press the emergency stop switch, disconnect the motor power supply, and use the machine to emergency stop.

3. After the operation of the film winding machine is over:

Please unplug the power plug when the machine is not in use. The main parts and components should be frequently lubricated with oil. After finishing the work of the day, the machine should be cleaned once.

To ensure safety, only electrical technicians can overhaul electrical equipment.

When repairing the winding machine, the maintenance personnel first confirm that the power supply is not connected, and if the maintenance personnel can repair it, then perform the maintenance.

If the maintenance personnel cannot perform the normal maintenance, they can contact the supplier for the maintenance, and do not do it blindly. .

For the safe operating procedures of the film winding machine, the company must formulate appropriate safe operating procedures based on the actual situation of the film winding machine after purchase, and requires employees to operate in accordance with the operating procedures, because this can ensure our production safety.

Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES