By Stretch Wrapper | 30 May 2023 | 0 Comments

Why is puncture resistance so important for stretch film?

Stretch film, also known as stretch wrap, shrink film and shrink wrap. Most of the stretch films in the early days were blown films. At present, stretch films are mainly produced by casting method. This is because the stretch films produced by casting lines have the advantages of uniform thickness and high transparency, and can be applied to the requirements of high-ratio pre-stretching. Because single-layer casting cannot achieve single-sided sticking, so its application is not as wide as three-layer casting process stretch film, and high-quality stretch film should have high transparency, high longitudinal elongation, and high yield point. High transverse tear strength, good puncture performance and so on.

Do you know what are the uses of stretch film?

1. Pallet packaging: Wrap the goods on the pallet or trays to form a whole to prevent loosening, collapse, and deformation during the turnover in the factory or during logistics transportation; and play the role of waterproof, dustproof, and anti-theft.

2. Carton packaging: Using stretch film as the packing film can protect the carton from rain, and at the same time avoid the loss of scattered items inside after the carton is broken by express violence.

3. Product surface protection: The stretch film has good self-adhesiveness, but it will not form glue residue on the wrapped object. It can be attached to smooth surfaces such as glass, building materials, ceramics, doors and windows to prevent being scratched by sharp objects.

How to choose the good stretch film?

With the help of the super wrapping force and retractability of the film, the stretch film bundles the product compactly and fixedly into a unit, and the product will not loosen or separate even in an unfavorable environment. Therefore, the stretch film should have good puncture performance and transverse tear strength to ensure that the film does not break when encountering sharp objects under high stretching ratios.

Puncture resistance is a guiding indicator for evaluating the ability of packaging to resist piercing by sharp and hard objects. During the long-term contact with the packaging, if the product contains sharp and hard substances, it is easy to have a strong puncture effect on the stretch film. If the puncture resistance of the stretch film is poor, it is easy to be punctured by sharp objects and damaged, resulting in loose separation of products or goods, which cannot play a protective role. This is why stretch film packaging should have high puncture resistance.

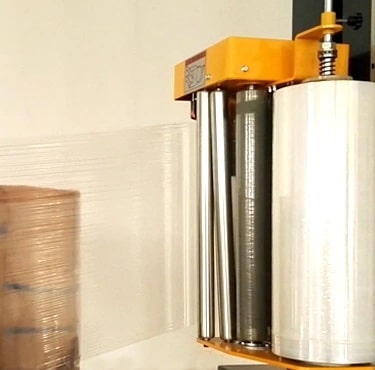

Puncture resistance is a guiding indicator for evaluating the ability of packaging to resist piercing by sharp and hard objects. During the long-term contact with the packaging, if the product contains sharp and hard substances, it is easy to have a strong puncture effect on the stretch film. If the puncture resistance of the stretch film is poor, it is easy to be punctured by sharp objects and damaged, resulting in loose separation of products or goods, which cannot play a protective role. This is why stretch film packaging should have high puncture resistance. For the stretch wrap machines that are popular now, most of them use the pre-stretching method to provide the compact effect of the wrapped package, and at the same time save the amount of stretching film used. The pre-stretching works through the motor-driven pre-stretching rollers, so compared with the manual wrapping method, it has higher requirements for the puncture resistance of the stretch film.Emanpack provides high quality stretch film with good puncture resistance. Our stretch film is widely used on different types of stretch wrap machine, with good experience and high quality, makes the perfect wrapping to give protection to your products.

For the stretch wrap machines that are popular now, most of them use the pre-stretching method to provide the compact effect of the wrapped package, and at the same time save the amount of stretching film used. The pre-stretching works through the motor-driven pre-stretching rollers, so compared with the manual wrapping method, it has higher requirements for the puncture resistance of the stretch film.Emanpack provides high quality stretch film with good puncture resistance. Our stretch film is widely used on different types of stretch wrap machine, with good experience and high quality, makes the perfect wrapping to give protection to your products.Leave a Reply

Your email address will not be published.Required fields are marked. *

CATEGORIES