Thermo shrink wrap machine, continuous motions for package side sealing and heat oven shrinking. Making tight and transparent package to against dust, rain and other damages.

Fully weld package without a leak, insolate the air , vapor and dust.

A transverse heat sealing blade for cutting and sealing the ends at once.

Side sealing device to seal the edge continuously.

Heat shrink oven for shrinking the wrapped products to make tight packages.

Features

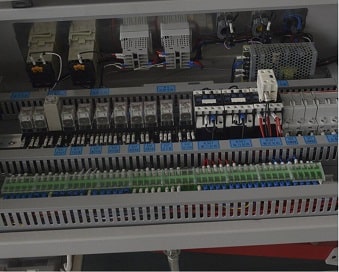

PLC programming for the machine's control and operation.

Clear icons displayed on the HMI, convenient for the workers to use.

Buttons made on the operation panel, make the machine in control when emergency happens.

Automatic sensoring, detecting the goods without any manual assistance.

Automatic start to save more time and improve the efficiency.

Delay time is adjustable according to your needs of your specific circumstance.

POF film is used as the packing material of this machine.

Temperature of the shrink oven is adjustable for different products and different requirement for temperature.

Excellent exterior of the shrank package, transparent and tidy.

Technical Parameter

| Sealing type | side sealing |

| Power supply | 380V/50-60Hz/3phase (available to customize) |

| Sealing height | 300mm |

| Product size | 400mm < widh + height < 800mm, length > 250mm |

| Product length | unlimited |

| Packing capacity | upon product's length |

| Film type | single layer PE film, POF film |

| Max film roll dimension | 860mm(width) x 280mm(outer diameter) |

| Power consumption | 18kw |

| Heat tunnel conveyor | chains with silicon coated rods |

| Air pressure | ≤0.5MPa |

| Sealing system | Special durable alloyed sealing knife with anti-stick Teflon coats |

| Weight | 800kg |

Optional Accessories

Conveyor belt

for in-feeding and out-feeding as well as interval transfer

Pusher

for the in-feeding of specific products

Front mechanism

for aligning and stacking of variant products