Pallets are necessary carrier in the production process. It functions as moisture-proof and easy to transport. Whether in clothing, toy factories, or home appliance production workshops, we can see a large number of pallets used to store and carry goods.

In raw material industries such as chemicals, food and building materials, due to the huge throughput of goods, pallets are used more frequently. For example, the daily output of a small flour mill can reach 50 tons, the daily output of a medium-sized chemical plant is 500 tons, and the daily output of a large cement plant can reach 10,000 tons.

How to package the palletized goods quickly and effectively is a very challenging task. Ordinary manual wrapping is not only inefficient but also has poor packaging performance. You can imagine how much strength a worker can have to make every round of wrapping has the appropriate tension when he is holding a roll of 5kg stretch film. At the same time, manual wrapping also has other disadvantages, such as slow packaging speed. And walking back and forth during wrapping consumes a lot of physical energy on workers. Frequent bending can cause back pain and other work-related injuries.

So How to Choose A Pallet Wrapping Machine?

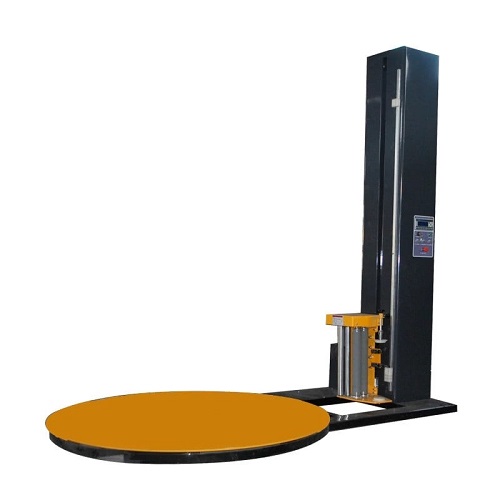

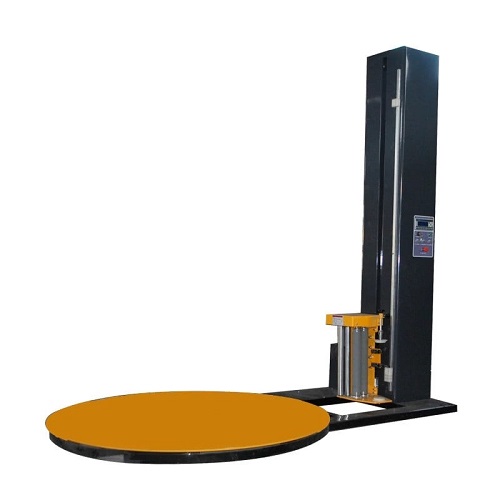

1. For small factories with low throughput and no production lines, the turntable pallet wrapping machine is the best choice. It is cheap and easy to operate. The pre-stretching function allows the machine to use less packaging materials than manual wrapping, and the wrapping effect is better and tighter. Moreover, the machine is small in size and fixed on its dead weight, making it easy to move the machine and facilitate changes in the layout of the plant in future.

2. For medium-sized factories equipped with production lines, online pallet wrapping machines are more suitable. It can be paired with an automatic conveyor line and connected to the production line to automatically wrap pallets. While improving packaging efficiency, it also reduces the number of personnel required, contributing to the factory's reduction in labor costs.

What Kind of Pallet Packaging Machine is More Suitable for Large Factories with Huge Throughput?

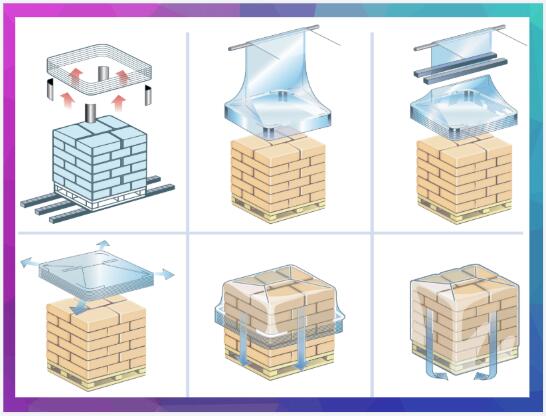

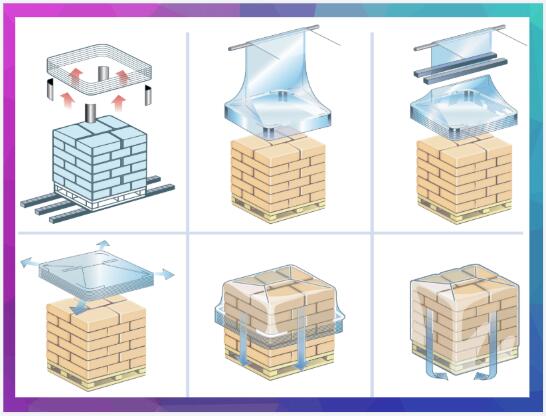

This brings up the pallet stretch hood machine. This is a pallet packaging machine that is completely different from the pallet wrapping machine. It uses stretch hood film to cover the entire load from top to bottom. It's like putting a hat on the goods. Its packaging speed is extremely fast, up to 120 pallets/hour. This is something that a pallet wrapping machine cannot achieve.

In addition, it has more advantages.

Compared with Stretch Wrapping Equipment

The

stretch hooder uses tubular film to pack the pallet, and the film will automatically adapt to the goods and protect the 5 sides of the goods. On the other hand,

stretch film machine uses more film to wrap the goods, and also requires an additional cover on top to protect the top of the goods.

Save Film:

Save Film:

Stretch hood machine can save the consumption of film, because stretch film packaging equipment needs to repeatedly wrap multiple turns around the pallets and also needs to wrap the top separately.

Protection from External Factors:

Stretch hood is complete five-sided packaging which is water-proof, protect goods from external factors such as wind, dust, UV rays, and even moisture, rain and snow.

Transparency and Visibility:

Because there is only one layer film, it is completely transparent and can clearly identify the brand and label of the goods.

Irreparable:

Irreparable:

Stretch hood film requires more than 1000kgf to pull the film apart and cover it on the surface of the goods. After packaging is completed, any infringement on the goods is easily detected because the film has only one layer and no wrinkles or film accumulation.

Best Packaging Quality:

In addition to the high transparency of the film, the stretch hood on the goods is smooth. The surface of the film can also be printed with the company's logo in advance, which can improve the quality of the goods.

Faster Packaging:

Fast speed, maximum packaging capacity of up to 120 pallets per hour, good weather resistance.

It still has good clamping force and stability from -20C to 0°C, and the clamping force perpendicular to the film direction is significantly improved, so the loadability is good and better than stretch wrapping.

In raw material industries such as chemicals, food and building materials, due to the huge throughput of goods, pallets are used more frequently. For example, the daily output of a small flour mill can reach 50 tons, the daily output of a medium-sized chemical plant is 500 tons, and the daily output of a large cement plant can reach 10,000 tons.

In raw material industries such as chemicals, food and building materials, due to the huge throughput of goods, pallets are used more frequently. For example, the daily output of a small flour mill can reach 50 tons, the daily output of a medium-sized chemical plant is 500 tons, and the daily output of a large cement plant can reach 10,000 tons. 1. For small factories with low throughput and no production lines, the turntable pallet wrapping machine is the best choice. It is cheap and easy to operate. The pre-stretching function allows the machine to use less packaging materials than manual wrapping, and the wrapping effect is better and tighter. Moreover, the machine is small in size and fixed on its dead weight, making it easy to move the machine and facilitate changes in the layout of the plant in future.

1. For small factories with low throughput and no production lines, the turntable pallet wrapping machine is the best choice. It is cheap and easy to operate. The pre-stretching function allows the machine to use less packaging materials than manual wrapping, and the wrapping effect is better and tighter. Moreover, the machine is small in size and fixed on its dead weight, making it easy to move the machine and facilitate changes in the layout of the plant in future. 2. For medium-sized factories equipped with production lines, online pallet wrapping machines are more suitable. It can be paired with an automatic conveyor line and connected to the production line to automatically wrap pallets. While improving packaging efficiency, it also reduces the number of personnel required, contributing to the factory's reduction in labor costs.

2. For medium-sized factories equipped with production lines, online pallet wrapping machines are more suitable. It can be paired with an automatic conveyor line and connected to the production line to automatically wrap pallets. While improving packaging efficiency, it also reduces the number of personnel required, contributing to the factory's reduction in labor costs.

Save Film:

Save Film: Irreparable:

Irreparable: