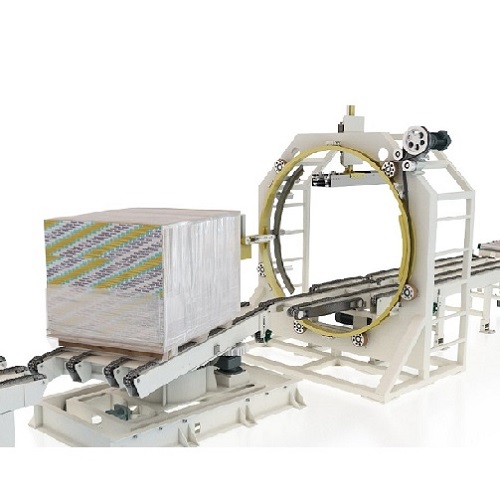

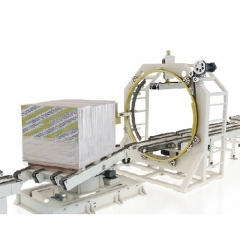

A fully automatic orbital wrap machine to stretch wrap bundles from both vertical and horizontal directions on one machine. A turnkey solution for packing gypsum boards and other products with fully sealed packages. Automatic insert wooden blocks under the bundle, greatly improve the capacity of packaging.

A turnkey packing solution for products such as gypsum boards, MDF boards, polymer coated steel sheet...

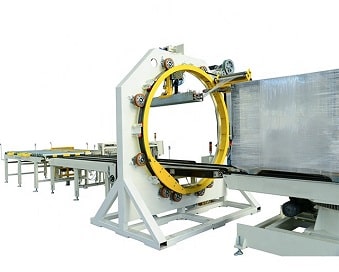

Super large turning ring for packing big sized bundles of boards and products.

Conveyorized turntable customized for rotating large bundles, stretch wrapping both on vertical and horizontal directions.

High tension for stretch wrapping, fully sealed package is about to against damages such as dust and vapor.

Features

Complex wrapping procedures, motion controlled by PLC program.

HMI for better and more convenient operation.

Conveyor speed control and regulated by frequency inverters.

Automatic photocell electricity for detecting the products, automatic program running.

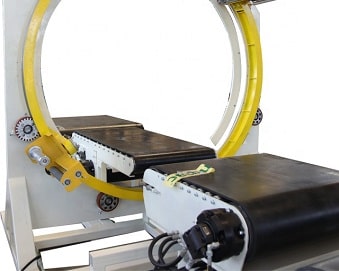

Chain conveyors are choosed as the best conveying parts to match with the products.

Film carriage is available to change positions for different wrapping directions.

Large film spool with wide material width for improving the packing efficiency.

Automatic timber feeding unit is optional to add, to insert wooden blocks under the bundle before wrapping.

Technical Parameter

| Ring diameter | 2400mm, 2800mm(depends on the bundle dimensions) |

| Bundle size | L: 1500-3000mm, W: 800-1500mm, H: 1000-1500mm ( customized according to product's sizes) |

| Max load | 3000kg (available to customize and improve) |

| Film roll dimension | |

| ID( paper core) | 76mm, OD: max 250mm, Width: 500mm, Weight: max 10kg |

| Speed of turning ring | 20-40rmp |

| Packing speed | 40-70 sec/package |

| Operation mode | one-button start |

| Power supply | 380V, 3Ph, 50/60Hz( 480V/570V.... available to customize) |

| Compressed air supply | 3-8kgf/cm² |

| Output | 5.5kw |

| Packing dimension | Per final design |

Optional Accessories

Timber feeding unit

for inserting wooden blocks under the bundles before wrapping

Combined conveying system

for better transferring products efficiently

Weighing scale

for weighing the goods more conveniently