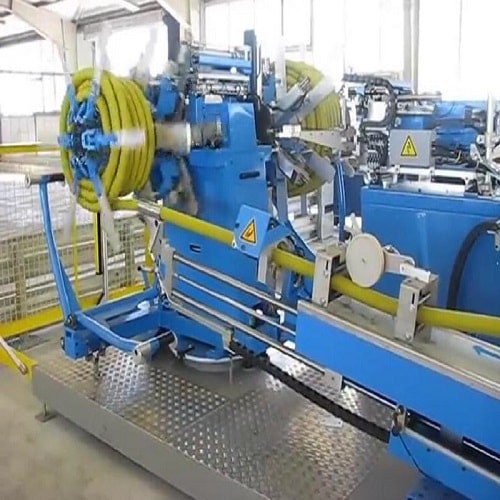

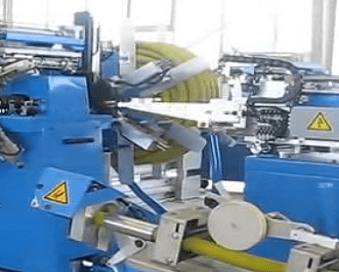

EM-CY1200 Auto pipe coiling and strapping machine,the machine can be connected to the hose extrusion production line for online packaging...

PLC & HMI control program for automatic operation.Coiling ID and OD can be adjustable per your need.

All conform to CE guidelines and have been designed using the latest technology and design criteria for plastic pipe industrial using.

Features

Parameters be set on the control program in English.

PLC & HMI control program for automatic operation.

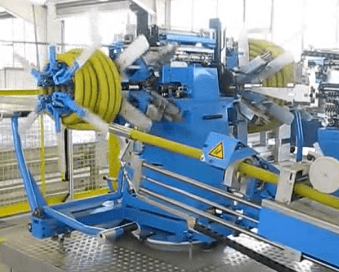

Strong driving for big and hard hoses coiling.

Calculate hose length and cut the hose automatically.

Tension control for hose in feeding for tight coiling.

Detect hose position automatically by sensor.

Indicator alarms automatically when trouble occurs.

Detecting the tube position infeeding automatic by sensor.

Tension control for avoiding deforming in coiling.

Coiling a hose roll orderly and nicely.

Pneumatically pushing device discharge the hose coil.

The strapping station is able move forward and backward for automatic strapping.

Automatic strap the coil by 2 or 4 or 6 positions.

Technical Parameter

| Hose Diameter | Φ40mm-Φ75mm |

| Coiling ID | 450-800mm |

| Coiling OD | 900-1200mm |

| Coiling Height | 250-400mm |

| Coil Weight | 100-300kg |

| Meter counter | 25-100 meters |

| Coiling speed | Max. 30m/min (adjustable) |

| Strap position | 4 straps |

| Strap material | PP strap Width:13mm Thickness:0.6mm |

| Power supply | 380V, 3Ph, 50/60Hz( 220V, 480V.... available to customize) |

| Coil feed style | Hold coil type |

| Air Supply | 6bar |

Optional Accessories

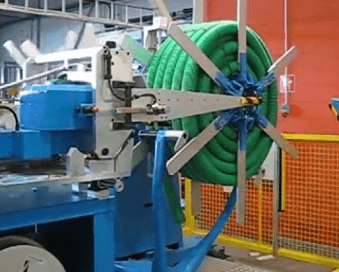

Auto coil stacking

auto holding finished hose coils one by one to stacking system for pallet arrangement.