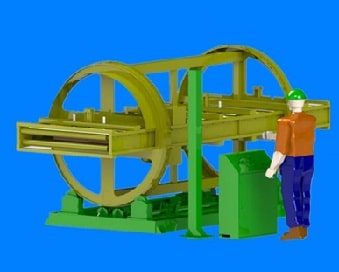

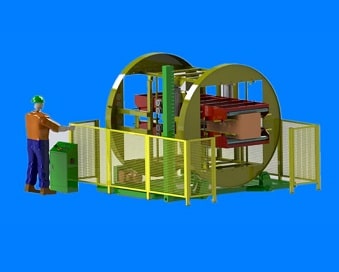

Learing from the O shape pallet inverter machine, this inline panel bundle inverter machine is an upgrade for the ply-wood bundle upender machine. Widely used for the wood manufacturing industry and it's an automated equipment which can be connected with other machinery to make the whole manufacturing system more efficient.

O shape turnover body easy to make the flipping of 180 degree under automatic control program.

Roller conveyors are built on both upper and bottom panels to forward the panel with connection to other related machinery.

Top press plates powered by pneumatic cylinders ( hydraulic cylinders for specific needs) to clamp the panel steadily during flipping motion.

Features

180 degree panel flipping, up-ending wooden panels continuously in line.

Pneumatic cylinder driven top clamp to fix the panel during rotation.

Clamp driven by hydraulic cylinder is optional, applied to heavy steel plates or doors.

Photoelectricity adopted to detecting the incoming of panels or other turnover products.

Optional to have new design for the forwarding direction or the machine structure.

Capable to used for variant dimensions and loads.

Smooth, accurate, vibration-free motion.

Simple control system with limited control buttons.

Operation is simple, non-professionals are able to manage, no need for training.

Strong structure makes the machine durable.

Technical Parameter

| Degree of tilting | 180° |

| Bundle dimension | (Max) L3000mm * W1600 * H500mm (customization is provided) |

| Clamping range | 200-600mm (customization is provided) |

| Max load | |

| FZ-PB-01 | 1T |

| FZ-PB-02 | 2T |

| Platform dimension | depending on product's dimension |

| Turn over speed | 40-60 sec/direction |

| Operation mode | button control |

| Power supply | 380V, 3Ph, 50/60Hz( 220V, 480V.... available to customize) |

Optional Accessories

Hydraulic cylinder

for clamping heavy loads

Combined conveyors

two forwarding directions on the same machine