For jumbo roll and paper napkin manufacturers, our TP-JP165 model can be a necessary equipment for their businness. This machine is good to embed under floor, convenient to load and discharge the heavy rolls by pushing manually on the floor.

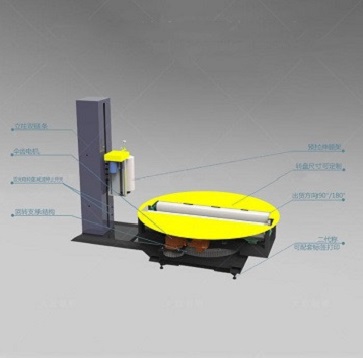

This particular machine is designed for stretch wrapping roll shape products with HDPE and other plastic film or foil. Pre-stretch the film to make the wrap tighter.

Available to add accessory devices to the machine body for more convenient and efficient work. weighing sacle is for weight indication and automatic printer connected for instant printing of information such as weight and commodity model.

Ejection device for automatic push out after wrapping, easier for workers outloading the products.

Features

Control panel built in the mast.

Display for setting, one button start wrapping automatically.

PLC control system, famous brands are adopted.

Automatic height sensoring, detecting the top of goods without any manual assistance.

Pre-stretch function, tighten the package and use less packing material.

Adjustable tension control, available for different packing material.

Adopt slewing bearing for rotation of the turntable with rolls on it.

Supportive rollers powered by electric engine, drive up the jumbo roll to rotate.

Initial position automatic return after wrapping.

Speed of turntable and film carriage are controlled by inverters, prevent potential risks for engines and extend the worklife of machine.

Reserved forklift notch, easy for relocation.

Technical Parameter

| Turntable Diameter | 2000mm/2200mm/2400mm......(available to customize) |

| Roll diameter | 500-2000mm (customization available) |

| Roll width | 500-1650mm/1850mm/2050mm....(customization available) |

| Turntable height | 460/520mm |

| Max load | 2000kg/2500kg/3000kg (available to customize) |

| Film roll dimension | ID( paper core): 76mm, OD: max 300mm, Width: 500mm, Weight: max 15kg |

| Pre-stretch ratio | 250%/300% |

| Speed of turntable | 0-12rmp |

| Operation mode | one-button start |

| Power supply | 220V,1/3Ph, 50/60Hz( 110V, 380V.... available to customize) |

| Output | 1.55kw |

| Packing dimension | L2620mm*W2220mm*H1500mm |

| Gross weight | app 1200kg |

Optional Accessories

Top press platen

for fixing tall and thin rolls during wrapping

Weighing scale

for weighing the goods more conveniently

Printer

for information label printing

Ejection mechanism

for roll pushing out after wrapping, convenient for unloading