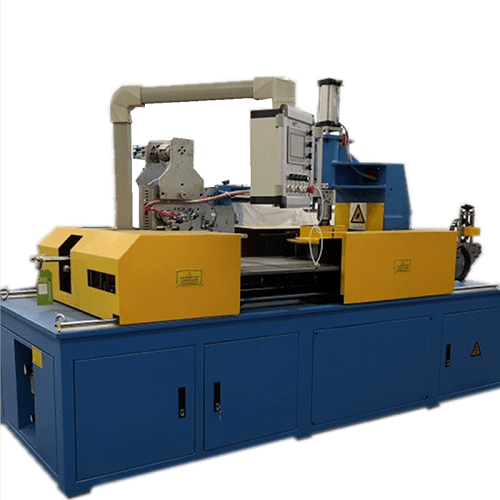

EM-CS400 Auto cable coiling and strapping machine, with cable length counting, coil making,automatic cutting,strapping with PP belt, and heat shrinking packing functions...

High-speed line arrangement system, neat and beautiful line arrangement.It is necessary to replace different coil reels head per different coiling inner diameter.

All conform to CE guidelines and have been designed using the latest technology and design criteria for plastic pipe industrial using.

Features

Parameters be set on the control program in English.

PLC & HMI control program for automatic operation.

Coiling length per coil can be set per requirement.

Auto cutting off after coiling making successfully.

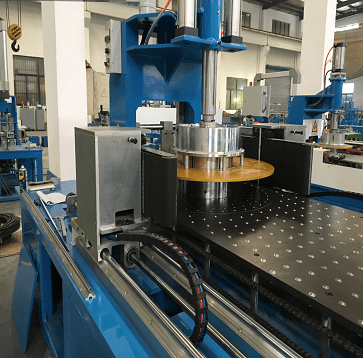

Coiling OD can be adjustable.

High-speed line arrangement system, neat and beautiful line arrangement.

Indicator alarms automatically when trouble occurs.

Detecting the tube position infeeding automatic by sensor.

Tension control for avoiding deforming in coiling.

Manual and automatic working mode can be choosing.

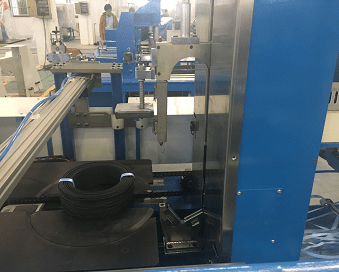

One side type or 2 places strapping per coil.

Automatic positioning for different coils for strapping with PP belt.

Strapping coil height min 44.5mm.

Technical Parameter

| Cable Diameter | 3-10mm |

| Coiling ID | 150mm |

| Coiling OD | 200-400mm |

| Coiling Height | 50-120mm |

| Line speed | 200m/min |

| Coiling speed | 2-2.5 coils/min |

| Air supply | 6bar |

| Coil feed style | Hold coil type (sensor) |

| Meter counter | 0.01m-500m |

| Power supply | 380V, 3Ph, 50/60Hz( 220V, 480V.... available to customize) |

| Strap width | 13mm |

| Strap thickness | 0.6 mm |

| Type of strapping | Polypropylene |

| Strap quality | Smooth /High quality |

| Type of joint | By friction - vibration |

| Joint efficiency | Approx. 75-80% of the breaking load of the strap |

Optional Accessories

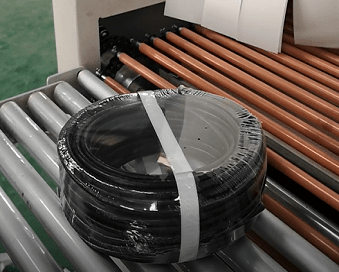

coil shrinking packing

auto sealing and shrinking packing after coil strapping.