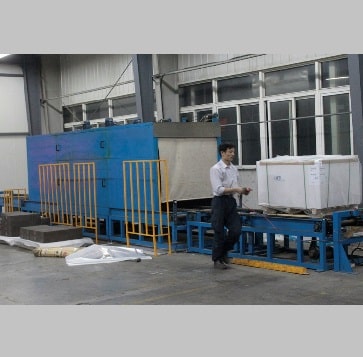

A customized packing solution for big and heavy pallet loads, large shrink tunnel to allow big pallets to go through. Automatic conveying system of chain conveyor to bear the heavy weights........

Large heat shrink tunnel with enough space of the chamber.

Chain conveyor for bearing the heavy loads of the pallets.

Reinforced insulation for reducing more heat loss and save more energy.

User friendly operation panel for the workers to better understand the control system.

User friendly operation panel for the workers to better understand the control system.

Features

Precise temperature control by temperature compensation system.

Heavy duty and high quality components rugged construction provides continuous operation with minimal maintenance.

Recirculation heating system consumes less electricity by minimizing heat loss.

Cooling device can cool down the products rapidly after the shrinking process.

High standard motors used to resist the high temperature of the environment.

Air circulation inside the tunnel, distributing heat to every corner.

The pallets need to be wrapped by shrinkable film manually prior to the shrinking process.

Technical Parameter

| Power supply | 380V/50-60Hz/3phase (440V/480V are available) |

| Pallet size | Depending on customer's requirement |

| Packing capacity | Depending on the pallet size and film thickness |

| Power consumption | 50kw |

| Heat tunnel conveyor | chain type conveyor |

| Max load | 2000kg |

| Machine weight | App 4000kg |