Fully automatic "L" type sealing and shrinking machine SW-L400 is widely used in flow packaging of mass produced products.

With high efficiency, automatic film feeding and perforation device, the machine has perfect continuous performance.

Manual adjustment of film guide system enables the machine to cover a large range of product size.

The SW-L400 model also has a tight joint function, which is specially designed for packaging small products. When the size of the package changes, the adjustment is very simple, without changing the mold and bag form.

Features

HMI for setting re-adjusting and data input.

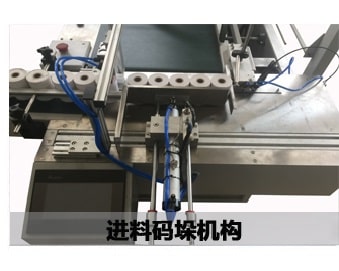

Automatic feeding, length can also be adjusted automatically by the combination of electric eye and timer.

Equipped with an induction motor to automatically take up waste.

Using the original "Omron" digital display thermostat, built-in PID function, the sealing temperature is extremely sensitive and accurate, and can be set at will.

The sealing knife itself also has an automatic protection function, which effectively prevents miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

According to different products, it is equipped with imported detection photoelectric, one set of horizontal and vertical detection, which is convenient to switch and choose.

For thin and small packaging, it can also easily complete the sealing and packaging operation.

Rollers of conveyor are made of silicion coated rods, able to resist high temperature.

The sealing knife adopts Teflon coating anti-sticking and high temperature resistant aluminum alloy knife, and the sealing will not crack, coke, smoke, and pollution.

Strong wind cooling system, cool down the products instantly after heat shrinking.

The entire machine is truly connected to the production line for automatic and human less running. The specially designed film up and down synchronization mechanism can correct film deviation.

Technical Parameter

| Sealing type | L-bar heat sealing blade |

| Power supply | 380V/50-60Hz/3phase |

| Product size | Width≤300 mm, Height≤125 mm |

| width+height≤380 mm, length+height≤480 mm | |

| Conveyor system | straight conveyor |

| Packing capacity | 10-25 packs per minute (depends on product size) |

| Film type | center-folded polyolefin(POF)film |

| Max film roll dimension | 530mm (width) x 280mm(outer diameter) |

| Power consumption | max. 12kw |

| Heat tunnel conveyor | chains with silicon coated rods |

| Machine material | carbon steel |

| Weight | 460kg |