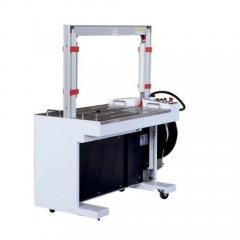

It's optional to choose this KZ-CS8060 as a semi-auto strapping machine, controlled by manual buttons or foot switch. Or use this machine to strap automatically with automatic control system and sensors of weight detecting or photoelectricity.

Automatic strapping machine for PP strapping material, automatic strap feeding system.

Tough and compact construction with a small footprint, mobile, with large table area and high capacity strap reel.

Simple, safe and user-friendly operation, automatic strap end detection.

Strap tension adjustable from soft to high, electronic heater temperature control.

Features

Automatic unmanned strapping machine is mainly suitable for strapping and packing of cartons, calcium-plastic case, soft and package as well as all kinds of articles in square, cylindrical..

Economical strapping machine to suit all applications and all budgets..

Adopt high-quality internal components to ensure that the machine can work continuously and stable.

Stainless steel working table and spherical sensory switch make the packing faster and easiser, improve working efficiency.

Automatic / manual / continuous packing, multiple options, high practicality.

The design of three built-in motors improves the packing speed and makes the machine more stable.

Adopt high-quality welding head, with high temperature resistance,more durable than traditional welding head, widened and reinforced welding head makes the deviation of bonding position smaller.

Technical Parameter

| Working height | 750mm(Available to customize) |

| Strapping speed | 2.5 seconds/strap |

| Max load | 80kg |

| Strap belt reel dimension | |

| ID | 200-210mm |

| OD | 400-500mm |

| Width | 160-180mm |

| Arch | Width:800mm * Height:600mm (able to customize) |

| Operation mode | Button/ foot switch/ weight sensoring/ photoelectricity |

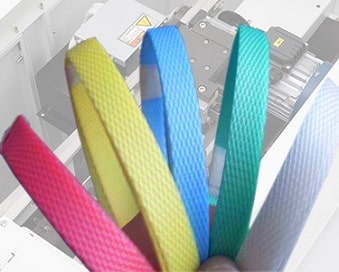

| Strap belt type | PP belt |

| Strap belt dimension | Width:9-15(±1)mm, thickness: 0.55-1.0(±0.1)mm |

| Strap tension | 0-80kg |

| Power supply | 220V 50/60Hz 1.0kw |

| Machine overall size | L:1400mm* W628mm* H1418mm |

| Gross weight | 150kg |

Optional Accessories

Roller conveyor

For inline automatic strapping with in-feeding and out-feeding system

Lower platform

Lower working heights to adapt to specific solutions and layout

PLC

Upgrade the control system from PC controller to PLC system for automatic inline strapping