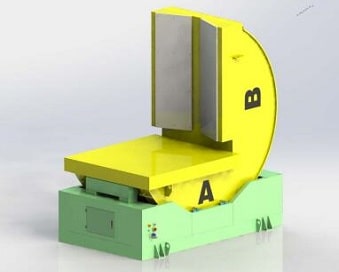

FZ-CT series inverters are turnover machineries for coil shape products, such as jumbo paper rolls, steel coils, aluminum coils, wire spools, reels and cord spools......

These products are heavy to up end, but necessary to turnover in some situations. For instance, steel straps are stacked and loaded on wooden pallets and need to change to vertical position before loaded on decoiler for studs and profile forming.

Sometimes, steel coils need to invert for placing a convector underneath before entering into the furnace to anneal or temper.

Features

90 degree upender, for coil related products.

V saddle for better fixing the coils steadily.

A cutout is optional for placing the pallet and make the position more centralized.

Surface is optional to cover with a layer of nylon boards for protect the products and reduce damages to the machine.

Supportive rollers for bearing the heavy load, make the rotation safe and stable.

Micrometric setting device make supportive rollers adjustable, ensure the machine runs smoothly.

Oblique gear and worm speed reducer with chain mechanism for driven the machine efficiently.

Speed is controlled by frequency inverter, easy to adjust and protect the motor.

Electric and Mechanical displacement restrictors adopted to guarantee a safety operation.

Position locking function allowing machine stop at any angle.

Automatically position fixing when power off for safety operation.

Individual electrical control panel away from the machine, more safe for users.

Simple control mode, no need for training.

Strong and durable structure, easy maintenance.

Technical Parameter

| Degree of tilting | 90° |

| Max load | |

| FZ-CT-05 | 5tons |

| FZ-CT-10 | 10tons |

| FZ-CT-20 | 20tons |

| FZ-CT-30 | 30tons |

| Platform dimension | upon product's dimension |

| Turn over speed | 20-50 sec/direction |

| Operation mode | button control |

| Power supply | 380V, 3Ph, 50/60Hz( 220V, 480V.... available to customize) |

| Noise level | ≤75DB |

| Work environment | humidity≤98%,temperature-10-40℃ |

Optional Accessories

Remote control

one forklift driver is enough to manage the work