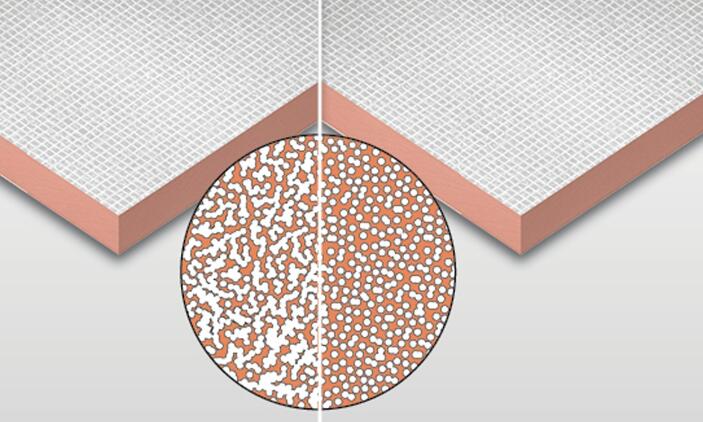

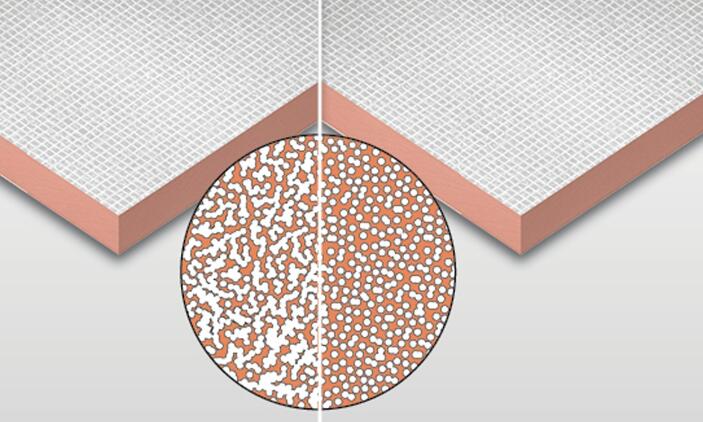

Phenolic foam insulation material is considered one of the best insulating materials. It has great physical properties, the closed cell formation rate is over 90% and the stability is good. Phenolic foams are available in different densities ranging from 35 kg/m3 to 200 kg/m3. High-density varieties such as insulation boards have good strength and are suitable for floor insulation.

It has low thermal conductivity. The thermal conductivity of phenolic closed-cell insulation materials is generally between 0.018W/m.K and 0.023W/m.K. It has flame retardant properties and low smoke levels (even under pyrolysis). This insulation material is waterproof and very lightweight, easy to transport and install.

Closed-cell phenolic insulation foam is resistant to almost all inorganic acids, organic solvents and acids. However, it does not perform well in alkaline environments. It does not show any noticeable aging when exposed to sunlight for extended periods of time. About its sound insulation, the phenolic panels have good sound absorption properties.

Environmental benefits of phenolic foam:

1. The energy per unit thermal performance of phenolic foam is very low;

2. Compared to other insulation materials phenolic foam has significantly less CO2 emissions;

3. Massive use of phenolic foam could make a significant contribution to helping achieve CO2 emissions;

4. Phenolic foam is available in CFC- and HCFC-free forms.

The most commonly used blowing agent in phenolic foam insulation is "pentane". This is to comply with EC regulations as it is free of CFCs and HCFCs, has no ozone depleting potential and has a low global warming potential. Pentane is a hydrocarbon. To prevent the blowing agent from escaping and being replaced by air, the insulation panels are covered with air-tight aluminum foil or cellophane.

Nowadays, more and more buildings are adopting this new insulation material. The consumption of phenolic foam panels and boards is substantial. But generally the phenolic foam panels are too large to pack by ordinary packaging machines such as

heat shrink wrapping machine. Besides, the phenolic foam panel is easy to deform by heating. So, people are looking for a practical wrapping machine for packaging the phenolic foam panels more efficiently.

This

orbital wrapper is very good for wrapping phenolic foam panels. It's making stretch wrapping on the long bundles of phenolic foam insulation materials. The machine doesn't apply any heat to the foam panels, won't deform its shape and the wrapped bundles are very tight with good protection.

Environmental benefits of phenolic foam:

Environmental benefits of phenolic foam: