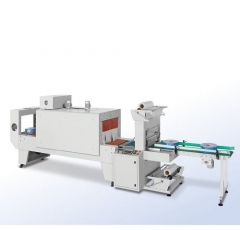

SW-S700 is a versatile thermal packing machine, by sleeve sealing and shrink wrapping, this machine is able to pack variant products such as grocery, cartons, foods and beverage on trays......

The machine covers the products a layer of shrinkable material before into the shrink tunnel.

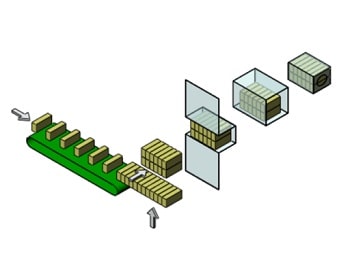

In-feed conveyor belt for the continuous in-feeding of products.

For packing beverage, the bottles and tins are better to be loaded on trays for the convenience of packaging.

Features

PLC program for machine control, easy operation and high efficiency.

Applying film on the product before shrinking by heat tunnel.

Continuous in-feeding with motorized conveyor belt or pheumatic pusher.

Heating sealing and cutting system with constant temperature for various industrial standard shrink films such as PE/POF.

Transverse heat sealing blade for cutting and welding the two layers of film together effectively.

Without replacement, very simple operation for maintenance.

Photoelectricity sensor used for detecting the products makes machine highly automated.

Insulation are applied to the heat tunnel, keeps more heat inside and reduces power consumption.

Air circulation inside the tunnel, distributing heat to every corner.

Cooling fans at the end of the packing line, chill the products within a quick time.

Technical Parameter

| Sealing type | sleeve sealing and shrink wrapping |

| Power supply | 380V/50-60Hz/3phase |

| Product size | 400(L) x 300(W) x 250(H)mm |

| Packing capacity | upon product's width |

| Film type | single layer PE film, POF film |

| Max film roll dimension | 650mm(width) x 280mm(outer diameter) |

| Power consumption | 12kw |

| Heat tunnel conveyor | chains with silicon coated rods |

| Air pressure | ≤0.5MPa |

| Sealing system | Special durable alloyed sealing knife with anti-stick Teflon coats |

| Weight | 700kg |