HM-A300 is an automatic horizontal orbital stretch wrapping machine, suitable for wrapping long shape products such as steel rod, steel tube, timber, aluminum profile....

Automatic film cutter clamps and cut the film controlled by the PLC program, no need for manual assistance.

Photoelectricity sensor detects the product and send the signal to PLC, partial wrapping is able to set for strapping bundles by stretch wrapping at few positions.

Features

PLC control system allows different settings and program.

HMI and buttons on control panel, convenient for operator to control machine and adjust settings.

Machine starts wrapping automatically when photocell detects the products, automatic film clamping and cutting when wrapping is finished.

Mushroom button, one press to stop the machine when emergency happens.

Ring speed and conveyor speed adjustable through frequency converter.

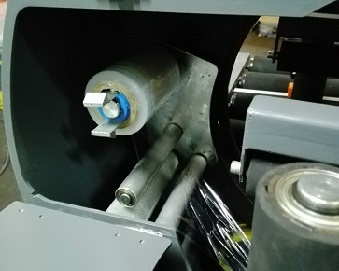

Film spool suitable for different materials.

Adjustable tension control, make tighter package.

Top press rollers and protective side rollers to fix the product and keep it stationary.

Technical Parameter

| Packing size | L800-unlimited, W50-250mm, H50-200mm (available to customize) |

| Max weight | upon customer's requirement |

| Film roll dimension | |

| ID | 50mm |

| OD | max 250mm |

| Width | 100-200mm |

| Stretch film thickness | 20-35 microns |

| Speed of ring rotation | 100-120rmp |

| Overlapping rate | 15-90% |

| Wrapping speed | 8-16m/min |

| Operation mode | automatic operation |

| Power supply | 380V, 3Ph, 50/60Hz( available to customize) |

| Output | 1.5kw |

Optional Accessories

Conveyor

conveyor belt, roller table, chain conveyor and chain board conveyor are optional, size depends on customer

Material cutter

Different types of film cutter for different packing material are available to choose

Film spool

Two film spools double the speed of wrapping