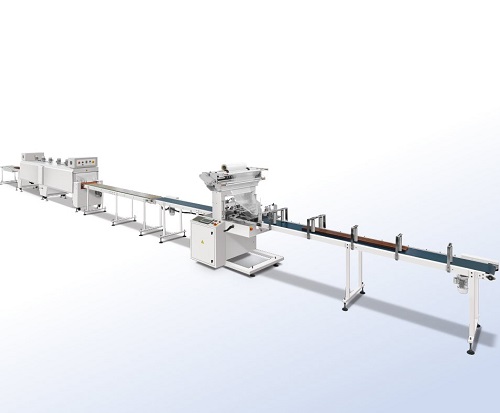

Back packing machine forms a bag and seals the plastic wrap on the back side. SW-B300 is built for products such as timber, rectangular tube, floor panel, bus bar, studs and aluminum profiles......

The machine is rewarded for it's fast speed and high standard performance. Back packing molds or forms are required, one machine is able to match with several different molds for different size package.

The machine is rewarded for it's fast speed and high standard performance. Back packing molds or forms are required, one machine is able to match with several different molds for different size package.

The package is fully sealed as one heat blade seals the ends before getting into the shrink tunnel.

Bottom lap sealing methods weld the joint area of the shrink film in the heat shrink tunnel.

The heat tunnel used insultation to keep more heat inside, greatly reduce the electricity consumption.

Features

PLC program for machine control system.

HMI for setting re-adjusting and data input.

Converters for speed regulating, extending worklife of the motors.

Package formed by back packing molds.

One machine is able to match with several different molds for different sized products.

Heat blade for sealing the ends of package.

Full sides are sealed before shrinking, the package is packed without a leak.

Rollers of conveyor are made of silicion coated rods, able to resist high temperature.

Adopt worm gear reducer, no vibration during in-feeding and film feeding.

Special sealer is used, the sealing is secure and not easy to open. No sticking to the sealer due to Teflon coating.

Conveyor made of PE material, high anti-abrasion and high strength.

Strong wind cooling system, cool down the products instantly after heat shrinking.

Optional to add roller table next to the exit of shrink tunnel, prevent falling to floor.

Technical Parameter

| Sealing type | bottom lap sealing |

| Power supply | 380V/50-60Hz/3phase |

| Product size | width+height≤400mm |

| Sealing height | ≤200mm |

| Conveyor system | straight conveyor |

| Packing capacity | depends on product length |

| Film type | polyethylene (PE) film |

| Max film size | 1000mm (width) x 280mm (outer diameter) |

| Power consumption | max. 22kw |

| Tunnel oven size | entrance 600(W) x 400(H) mm |

| Tunnel conveyor | chains with silicon coated rods |

| Working height | 850-900mm |

| Air pressure | ≤0.5MPa(5 bar) |

| Sealing system | Durable“U”shape alloyed sealing knife and saw teeth cutting knife with anti-stick Teflon coats |

| Operating panel | Touch screen, PLC, omron temperature controller |

| Machine material | carbon steel |

| Weight | 1200kg |