The model KZ-BS is designed for strapping and packing large bale cargo, this equipment has a wide range of applications in the cotton and chemical fiber markets.... The working mode is fully automatic with PLC control system and sensoring.

Automatic PET belt strapping with high speed friction sealing at the side of the bale.

Tough and compact construction with a small footprint, for large and tall cartons strapping.

Simple, safe and user-friendly operation, automatic strap end detection.

Strap tension adjustable from soft to high, automatic control system easy to adjust the settings.

Features

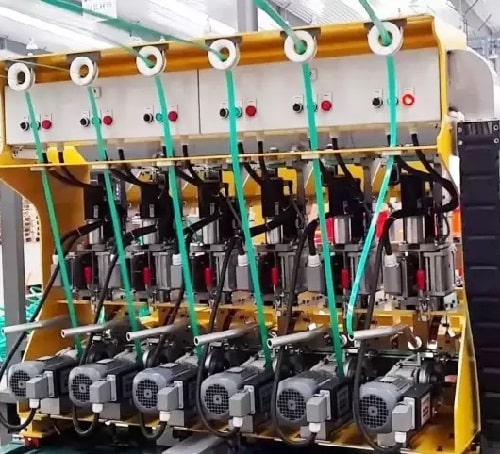

We can provide 2 heads, 4 heads, 6 heads, 8 heads equipment according to the customer's output.

Adopt international first-line brand device configuration, long service life, simple and flexible procurement.

Using rack and pinion method, stable operation at low temperature, faster speed and firmer.

Servo drive control, fast running speed, high positioning accuracy, 2 machine head equipment cycle faster than other similar brands.

Automatic and manual dual-function tape replenishment function, which can realize simple and fast tape replenishment at any position.

The equipment automatically measures the ambient temperature and intelligently adjusts the welding time to avoid human adjustment errors and ensure the welding quality.

Applicable to all pressing machines on the market, suitable for most PET belts on the market, with low requirements for belts and strong adaptability.

Technical Parameter

| Strap tension | 450N |

| Strapping speed | 7.0-9.0 seconds/strap |

| Strap belt reel dimension | |

| ID | 406mm |

| Width | 190±50mm |

| Welding size | 47mm |

| Sealing time | 1-1.5 second |

| Strap belt type | PET belt |

| Strap belt dimension | Width: 19(±1)mm, thickness: 1.2-1.4mm |

| Strapping speed | 90 seconds |

| Power supply | 380V 50/60Hz 5.0kw |

| Compress air supply | ≥0.55Mpa, 0.2³/min |

| Trolley | 25m/min |

| Strap head weight | App 37kg |