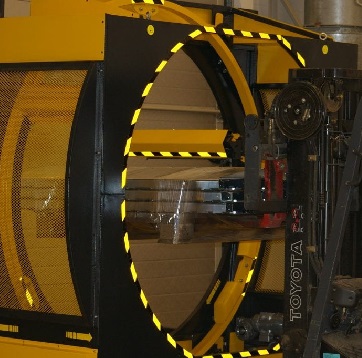

HM-S1400 is a special orbital stretch wrapping equipment designed for wrapping pallet loaded goods with forklift loading. The machine is large in size to match with pallet dimensions.

Large diameter of the rotating ring for high speed wrapping. The wrapping station is pushed by forklift driver during stretch wrapping. It's optional to upgrade this motion to automatic motor driven.

For specific demand and needs, programmable PLC could be added and adopt photoelectricity, automatic sensoring when goods approaches and machine automatic start and stop for wrapping.

Auotmatic material cutter driven by pneumatic cylinder for cutting and clamping stretch film after wrapping and load wrapping material for next turn.

Features

Large rotating ring for different pallet dimensions.

Big stretch film roll with wide width to improve the wrapping efficiency.

Optional to upgrade to motor driven motion for automated solution.

Mushroom button, to stop the machine when emergency happens.

Adjustable ring rotation speed through frequency inverter.

Stretch film tension could be adjusted to make tighter package.

Film spool is workable for different packing materials.

Automatic start and stop as well as automatic film cutter are available to add for fully automatic operation.

Fully automatic solution allows the machine to operated by only one forklift driver.

Technical Parameter

| Pallet size | L1000mm*W800mm/L1000mm*W1000mm L1200mm*W1000mm/L1200mm*W1200mm ( other dimensions are available to customize) |

| Max height | 500mm ( available to customize for higher height) |

| Film roll dimension | |

| ID | 76mm |

| OD | max 350mm |

| Width | 300-500mm |

| Stretch film thickness | 20-35 microns |

| Speed of ring rotation | 30-40rmp |

| Overlapping rate | 15-90% |

| Operation mode | semi-automatic operation |

| Power supply | 380V, 3Ph, 50/60Hz( available to customize) |

| Output | 1.25Kw |

Options

Motor driven solution

wrapping station moved and powered by motor

PLC program

for automatic wrapping start and stop

Film cutter

for cutting and clamping wrapping material when wrapping process is finished, automatic material loading for next turn