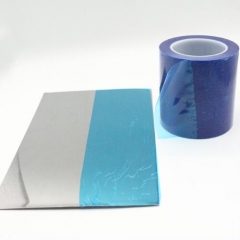

PE protective film is a plastic film made of polyethylene. It is used to attach to the surface of products to protect it from contamination, corrosion, scratches during production, processing, transportation, storage and use. Keep the original smooth and shiny surface, thereby improving product quality and market competitiveness.

Applications in hardware industry: computer casing, galvanized sheet stamping, aluminum profile, stainless steel plate, titanium plate, plastic steel plate, glass plate, solar panel, etc.

Plastic industry: ABS, PP injection molded products, PVC sheets, acrylic sheets, instruments, plastic lenses, surface protection of spray-painted parts, etc.

Electronics industry: to protect the finished products and semi-finished products from scratches and damage on the assembly line during production.

Features

The quality of the PE protective film is stable.

After peeling off, the glue will not fall off and no residual glue will be left on the surface of the product.

The adhesive is inert and doesn’t pollute or corrode, widely used on polished stainless steel sheets to prevent the contamination by dust, etc.

High elongation and strong fracture resistance and is widely used in many fields such as building materials, home appliances, and hardware appliances.

Good adhesion properties, no chemical reaction with the surface of the adhered material.

Available to prevent dirt accumulation, scratches and tool scratches during laser cutting operations.

Technical Parameter

| Jumbo roll width | 1200mm (default) |

| Sub-roll width | Depending on customer requirement |

| Length per roll | Depending on customer requirement |

| Inner diameter | 76mm (available to customize) |

| Thickness | 30-150 Microns (available to customize) |

| Viscosity | 270g/25mm (available to customize) |

| Charge unit | SQM/M |

Options

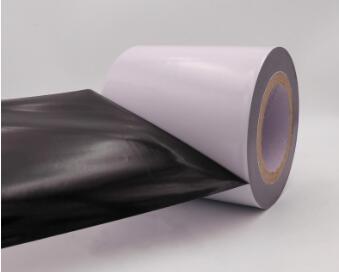

Color

different colors for different products, available for customization

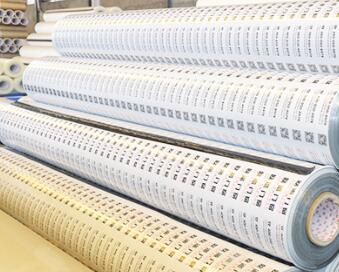

Printing

please contact us with your pattern