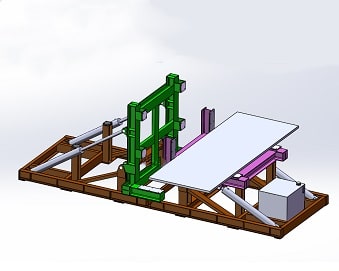

Making the flipping motion of large and heavy plates and panels such as pre-slab. Changing the upper surface with an easy and safe 180 degree turnover action. Replace the manual work and giving more protections to the operator. Using the forklift to cooperate instead of the hoist/crane, less dangerous operation and more quick actions.

Hydraulic cylinders used for driven the turnover machine smoothly with sufficient power.

Reinforced structure using thicker and stronger material with high standard and careful soldering.

Dual flipping bodies are optional for accomplishing the 180 degree turnover with twice rotation.

Features

An effective equipment for flipping the heavy bundles and panels/boards for exchanging the upper and down sides.

Safer operation compare to manual flipping by forklift and hoist.

Control by buttons and easy to operate, greatly reduce the labour intensity in the workshop.

Double flipping bodies to finish the 180 degree turnover with twice 90 degree turnover.

Fork shape workbenches crossed for the smooth handover of the heavy bundles.

Available to embed in the pit of floor for convenient loading and unloading by pallet jack.

Separated control panel and electrical cabinet away from the turnover machine, keep the personnel safe.

Multiple position limit system ensure secure operation, the machine can be stopped at random and object will stay in current position.

Low noise keep a friendly and comfortable environment for the workers.

The machine is integrally welded, polished, heat treated and adjusted.

Technical Parameter

| Degree of tilting | 90°/180° |

| Bundle dimension | depending on customer requirement |

| Loading | forklift/ hoist/ pallet jack |

| Max load | |

| FZ-PSB-01 | 1T |

| FZ-PSB-02 | 2T |

| FZ-PSB-03 | 3T |

| Platform dimension | depending on product's dimension |

| Turn over speed | 90-120 sec |

| Operation mode | button control |

| Power supply | 380V, 3Ph, 50/60Hz( 220V, 480V.... available to customize) |