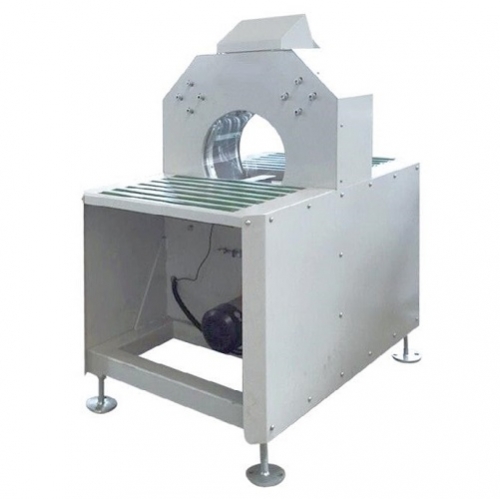

HM-S300 is a semi-automatic orbital wrapper, keep the easy control as the biggest point of the machine's feature......

The machine has unmanned roller tables for both in-feeding and out-feeding conveying. Foot switch to start and stop the rotation of the ring, giving good feeling of use to the operators.

Automatic cutter cut and clamp the wrapping material at the same time, efficient to finish the work and increase your capacity.

The machine is suitable for wrapping cartons, cardboard boxes, aluminum profile, steel studs, rods and bundles such as wooden posts, boards and panels.....

It's widely used in industries such as: aluminum extrusion, L angle bar, timber, steel production.

Features

Controlled byy PLC control system for automatic processing.

Foot switch to start and stop the ring rotation.

Machine cut the wrapping material automatically after rotation is finished.

Mushroom button, for stop the machine when emergency happens.

Ring rotation speed is adjustable through frequency inverter.

Stretch film tension could be adjusted to make tighter package.

Film spool is workable for different packing materials.

Top press rollers are optional to add to fix the product and keep it stationary.

Technical Parameter

| Packing size | |

| Length | 800mm-unlimited |

| Width | 50-150mm (available to customize) |

| Height | 50-200mm (available to customize) |

| Max weight | 50kg (available to customize) |

| Film roll dimension | |

| ID | 50mm |

| OD | max 200mm |

| Width | 100-150mm |

| Stretch film thickness | 20-35 microns |

| Speed of ring rotation | 100-120rmp |

| Overlapping rate | 15-90% |

| Wrapping speed | 8-16m/min |

| Operation mode | semi-automatic operation |

| Power supply | 380V, 3Ph, 50/60Hz( available to customize) |

| Output | 0.75Kw |