There are many types of aluminum profiles on the market, and aluminum profile surface treatment technology is also constantly improving. Currently, various aluminum profile surface treatment technologies include: mechanical polishing, chemical polishing, anodizing coloring, electrophoretic painting, chemical coloring, fluorocarbon spraying, electrostatic powder spraying, surface pattern treatment, etc. The subsequent processing steps of aluminum profiles generally include cutting, bending, drilling, stamping, etc.

That is to say, because the entire production and processing of aluminum profiles involves many and extremely complex processes, there are many cases where aluminum profiles are damaged due to improper operation. Therefore, during the transportation, storage, processing and assembly of aluminum profiles, the surface of the aluminum profiles need to be protected to prevent corrosion by harmful gases, microorganisms, dust pollution, mechanical scratches, scratches and other damage, so that the surface of the product retains its original high quality. And the smoothness improves the yield of secondary processing. In addition, it can also be used for temporary protection in electroplating, printing, coating, printing and dyeing, etc.

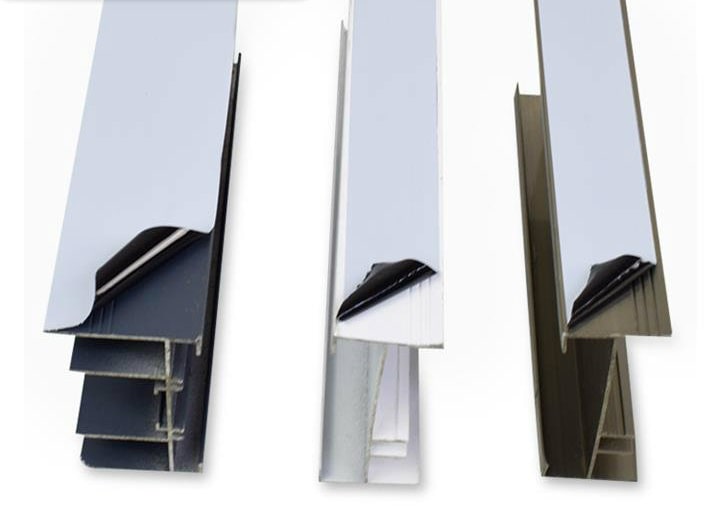

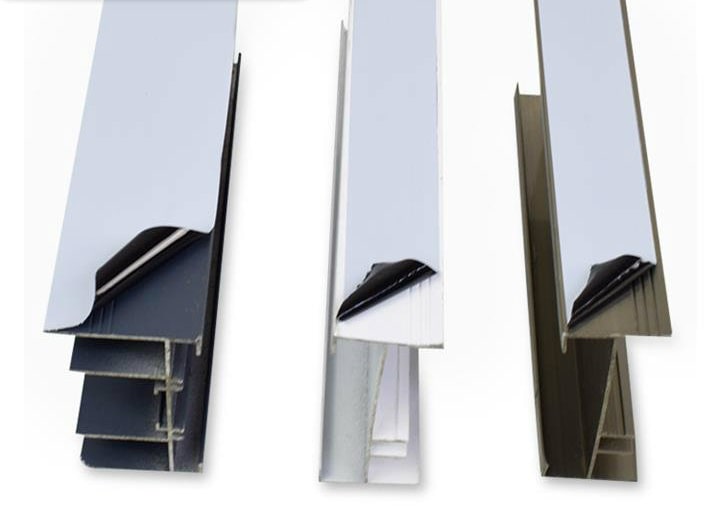

The most commonly used method to protect the surface of aluminum profiles is to put a protective film on the surface of the protected aluminum profiles. The protective film is a layer of plastic film attached to the aluminum material. The purpose is to protect the produced aluminum material from damage during a series of processes such as handling, storage, transportation, processing, and installation. After the aluminum material is installed, the installer tears it off to make the aluminum surface as smooth as new and have the proper decorative effect.

In this regard, our company has received feedback from some customers in the United States. For aluminum profiles with protective films, whether it is product sales or final project delivery, customers have recorded a very obvious reduction in the number and proportion of claims and complaints from end users.

How can We Reduce the Extra Workload caused By Sticking Films?

In fact, for the aluminum profile laminating work, we do not need to use manual methods to complete the work. We can easily accomplish this with the help of an

aluminum profile laminating machine. This machine uses rollers to drive the aluminum profiles forward. Multiple sets of rollers with polyurethane protective layers clamp the aluminum profiles from up, down, left, and right directions, effectively ensuring that the aluminum profiles advance at a uniform speed. Meanwhile, it can also ensure that the surface of the aluminum profile will not be damaged by scratches. The machine can place 4 rolls of protective film and apply it to 4 sides of the aluminum profile at the same time. For irregular aluminum profiles, we can also add the arches to the machine to install brushes and small 360-degree movable pressure rollers. By adjusting the settings, each surface can fit perfectly.

Perhaps, the scope of application of this aluminum profile laminating machine does not stop there. It has the same purpose for stainless steel profiles. High-end glass bathroom door manufacturers from the UK also tend to use this machine to protect their products with the stainless steel profiles.

The most commonly used method to protect the surface of aluminum profiles is to put a protective film on the surface of the protected aluminum profiles. The protective film is a layer of plastic film attached to the aluminum material. The purpose is to protect the produced aluminum material from damage during a series of processes such as handling, storage, transportation, processing, and installation. After the aluminum material is installed, the installer tears it off to make the aluminum surface as smooth as new and have the proper decorative effect.

The most commonly used method to protect the surface of aluminum profiles is to put a protective film on the surface of the protected aluminum profiles. The protective film is a layer of plastic film attached to the aluminum material. The purpose is to protect the produced aluminum material from damage during a series of processes such as handling, storage, transportation, processing, and installation. After the aluminum material is installed, the installer tears it off to make the aluminum surface as smooth as new and have the proper decorative effect.