The automatic cotton bale strapping system has the feature of very simplified maintenance, it can apply up to six straps simultaneously to eliminate the indexing time which is needed for applying multiple straps. The efficiency of using this machine enables you to gin more cotton with a faster speed which shortens your ginning season and reduces the overhead and labor costs.

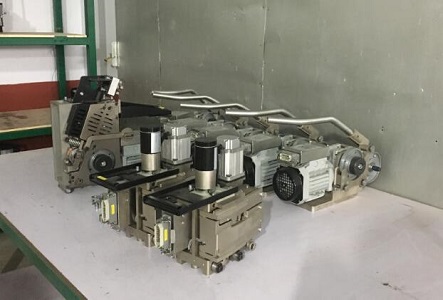

This cotton baling machine adopts international well known brands of components, using all-electric design seamlessly connected with the hydraulic cotton baler to implement unmanned and fully automatic operation. The main components adopt modular design, each module is completely independent of each other which makes the machine to realize offline maintenance of strapping head.

Because the weight is decomposed, each module can be easily lifted and replaced manually during use, realizing quick change technology and minimizing the downtime. The process of replace is very easy and can be mastered within one hour, no special training is needed.

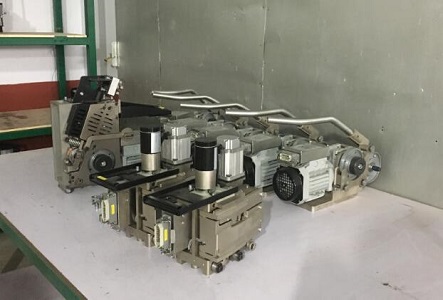

To remove a feeder module begin by putting the machine into service mode depending on your machine configuration. You may have to raise the carriage and insert a locking pin to access the feeder modules to remove any strap. To remove the module, disconnect the electrical quick disconnect cable. Release the pinch lever by pressing the release lever lift to remove the module. To reinstall a feed module slide the module back into the base, reconnect the quick disconnect cable and follow strap loading procedures.

To remove a sealer module begin by putting the machine into service mode depending on your machine configuration. You may have to raise the carriage and insert a locking pin to remove any strap. To remove the module, disconnect the quick disconnect cable, open the release lever located on the bottom of the module lift to remove the module. To reinstall the sealer module, slide the module back into the base, reconnect the quick disconnect cable and follow strap loading procedures.

Once any one or several heads are faulty, the other heads have the function of replacement, automatically complete the strapping of full belts. If you need to manually eject a bale out of the press take the strapping system out of automatic mode and place in manual mode on the key switch. Return the head carriage to home position by manually activating the head carriage home switch on the control panel. Manually activate the rear chute with either the up or back position switch, lock out the air supply and insert the locking pin after removing the bale. Be sure to remove the chute locking pin before turning the power on, and placing the system back into auto mode.

This fully automatic

cotton bale strapping system is compatible with most balers on the market. The high degree of automation, greatly improves your production efficiency and reduces the labor intensity. It's the ideal choice for large factories when thinking about an investment to improve the ginning capacity and reduce the overhead as well as labor costs.